News

Introduction to the Working Principle of the Cable Fault Indicator

Date:2022-12-12

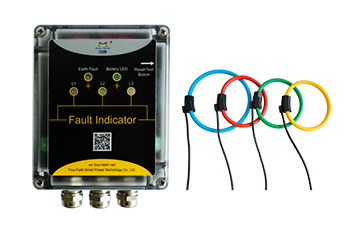

The cable fault indicator is an important equipment and instrument that can intelligently judge, detect and locate grid operation faults according to changes in current and voltage in the grid lines. It is usually installed in the power transmission network and is mainly used to monitor and detect possible short-circuit and single-phase grounding faults in the line. When a short-circuit occurs in the power network, the current value in the line changes suddenly, and the fault current When passing through the indicator, it will trigger the flop or flash action of the indicator, and the non-fault current will not affect its normal display. Today we take a detailed look at how the cable fault indicator works:

The two types of faults most likely to occur in power network transmission are phase-to-phase short circuit and single-phase grounding, so the design of the fault indicator is also set according to these two types of faults. Phase-to-phase short circuit refers to the mutual contact between two or three phases of the transmission line, resulting in the occurrence of line short circuit faults. When a short circuit occurs between phases, the instantaneous current in the line increases suddenly, and a sudden current jump is formed. The current mutation value is set inside the fault indicator. If the current change exceeds the set value, the indicator will display Corresponding fault signal.

For the judgment basis and principle of single-phase grounding, the zero-sequence current amplitude method is most used at present, that is, the temporary current, voltage and other data values are collected in the distribution network where the neutral point is not directly grounded, and then the steady-state zero-sequence method is used. The fundamental wave or higher harmonic of current and voltage calculates and analyzes the collected data, so that the current and voltage values in the line are judged. If it is a fault current, the display will turn over or light up, otherwise the indicator will not change.

The working principle of the cable fault indicator is that when a short-circuit fault occurs in the line, the short-circuit fault indicator senses the fault current, and the display window of the indicator will change from white to red (or glow). Accurate action, strong anti-interference ability: the signal is not affected by the line, excitation inrush current, high-order harmonics, current fluctuation, especially the cable distributed capacitance bypass. The fault section is easy to find: the indicator is directly installed on the distribution line, and the fault section can be easily found by checking whether two adjacent indicators operate or not. Automatic/manual reset: The indicator automatically returns to the normal position from the fault state after the action according to the reset time set by the factory; it can also be manually reset according to user needs.

When installing, you need to check whether it is opened in the original state, and separate the shell from the metal parts. Unscrew the screw; clamp the metal piece on the cable; clamp the housing with the metal piece; tighten the screw so that the indicator is fixed on the cable. Detection principle Short-circuit detection: Detect the current of the cable line, set a threshold value, and turn over after exceeding the set value and reaching the specified delay, indicating which phase has a short-circuit fault. Detect the zero-sequence current of the cable line and set a threshold value. After exceeding the set value and reaching the specified delay, the action will turn over to indicate which phase has a ground fault.

Short-circuit current alarm indication: The short-circuit detector detects the current in the power supply line at all times. When the value reaches or exceeds the short-circuit starting current, the short-circuit detection processor sends out a signal, and the indicator turns over to display. Automatic reset: After the indicator is displayed, if there is no manual reset within the set time, the indicator will automatically reset.