News

How to Choose the Right RTU for Power Grid Automation?

Date:2025-09-29

Selecting the right Remote Terminal Unit (RTU) for your power grid can be challenging. With so many options available—communication protocols, I/O capacity, local logic, and environmental resilience—how do you know which RTU will best serve your substation, feeder, or distribution network?

Before making a decision, it’s important to consider both the immediate impact on your grid monitoring and the long-term effect on your automation strategy. The ideal RTU should not only improve real-time visibility and control across your substations and feeders but also provide the reliability and scalability needed for future upgrades, smart grid integration, and efficient fault management.

What Does an RTU Do in a Power Grid?

In a modern electrical network, an RTU acts as the link between field devices and the control center. It collects real-time data from:

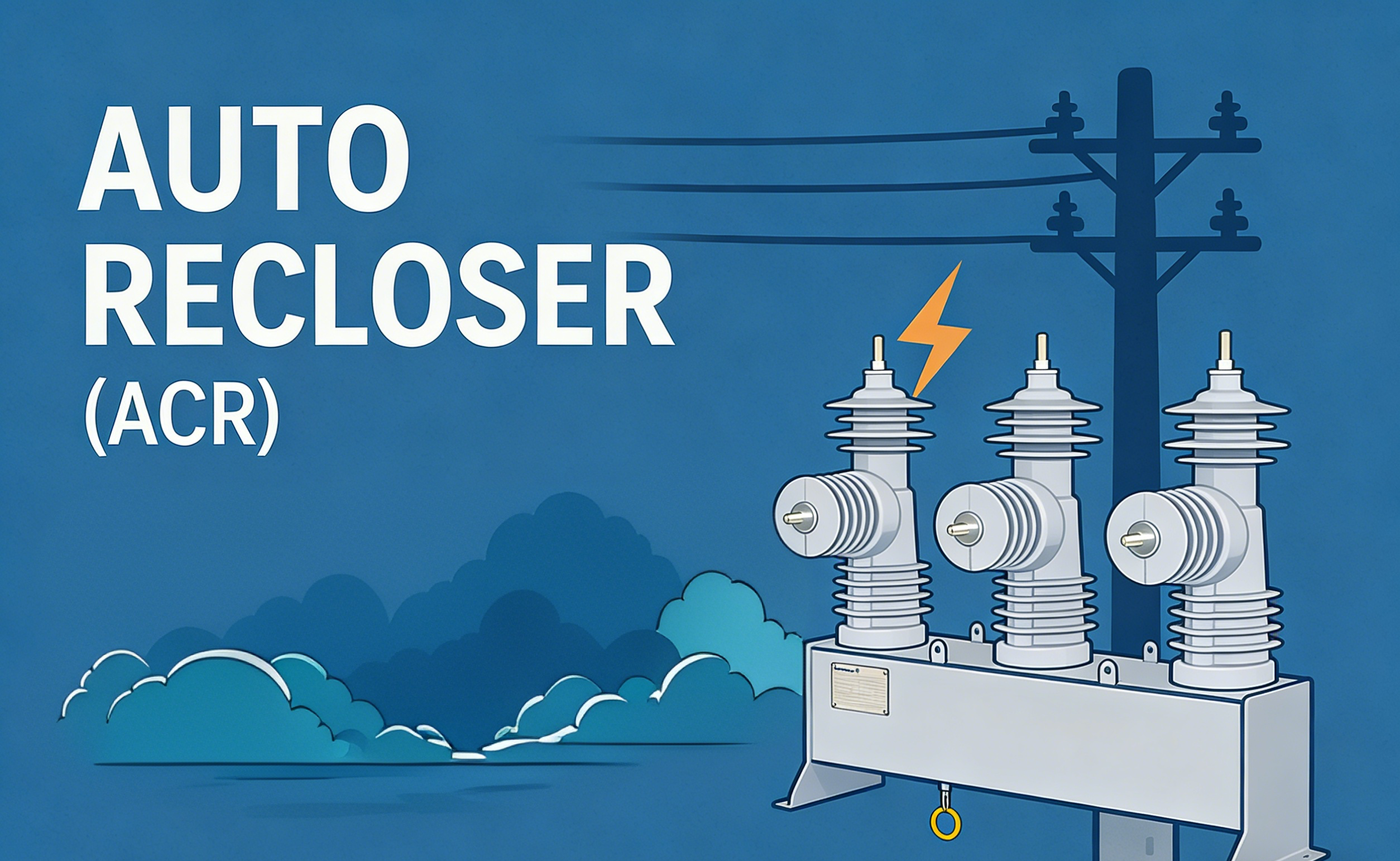

lCircuit breakers, reclosers, and switches

lFeeder protection relays and IEDs

lSensors measuring voltage, current, and power quality

The RTU transmits this data to your SCADA system and executes control commands from the control center, helping operators monitor grid health, respond to faults, and maintain stable, reliable electricity delivery.

Key Factors to Consider for Grid RTUs

1. Communication Protocols

Grid RTUs must communicate with multiple devices reliably. Look for support of:

DNP3, IEC 60870-5-104, Modbus,IEC 61850

Interoperability with SCADA and IEDs from different vendors

Secure and reliable transmission over wired or wireless networks

2. I/O Capacity

Power grid RTUs need sufficient I/O channels to handle:

Digital I/O for breaker status, switch positions, and alarm signals

Analog I/O for voltage, current, and other electrical parameters

Expandable modules for future substation upgrades or distributed energy resources

3. Local Logic and Automation

Modern RTUs can perform local control actions at substations or feeder points:

Tripping a breaker during fault conditions

Initiating recloser sequences automatically

Coordinating with protection relays for fast fault isolation

4. Reliability and Maintenance

Grid RTUs must withstand harsh environments:

High temperatures, humidity, and electrical surges

Remote diagnostics and firmware updates to reduce field maintenance

Long-term durability for uninterrupted power system operation

Comparing Different RTU Models for Power Grids

|

Feature |

Basic RTU |

Advanced RTU |

|

|

Communication Protocols |

Modbus only |

Modbus + DNP3 |

IEC 60870-5-104, DNP3, IEC 61850 |

|

I/O Capacity |

8–16 I/O |

32–64 I/O |

28 DI, 8 AI, 16 DO |

|

Local Logic |

Limited |

Moderate |

IEC 61131-3 Programmable Logic |

|

Cybersecurity |

Basic |

Advanced |

IEC 62351 Compliance, Role-based Access Control |

|

Modular Design |

No |

Yes |

Yes |

|

Horizontal GOOSE Support |

No |

No |

Yes |

|

Operating Temperature |

-20°C to +60°C |

-20°C to +60°C |

-40°C to +70°C |

|

IP Protection |

IP20 |

IP20 |

IP20 |

Note: The F-RLY600CR RTU offers superior features tailored for power grid applications, ensuring enhanced reliability and future-proofing.

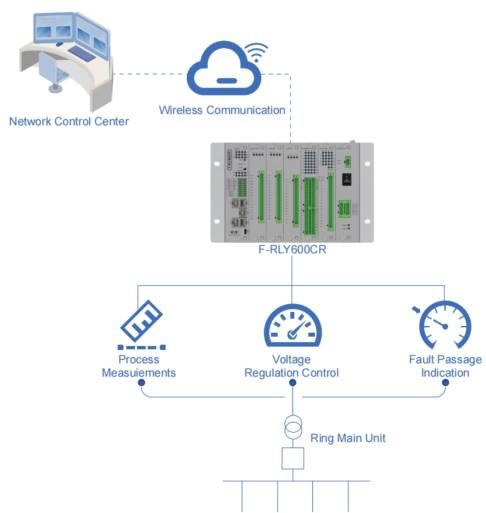

Why Choose the F-RLY600CR RTU for Your Power Grid?

The F-RLY600CR RTU stands out as a comprehensive solution for modern power grid automation. Here's why:

lAdvanced Communication Protocols: Supports IEC 60870-5-104, DNP3, and IEC 61850, ensuring seamless integration with SCADA systems and other intelligent devices.

lModular Design: Independent cards for MCU, power supply, analog, and digital I/O modules facilitate easy expansion and maintenance, reducing downtime and operational costs.

lProgrammable Logic: Complies with IEC 61131-3 standards, allowing for customized control logic, interlocking, and BATS (Break Before Make) functions, enhancing automation capabilities.

lCybersecurity Compliance: Adheres to IEC 62351 standards, offering secure SCADA communication and role-based access control to mitigate cyber threats.

lHorizontal GOOSE Communication: Enables self-healing and reliable distributed grid solutions without relying solely on the master system, improving grid stability and reliability.

lWide Operating Temperature Range: Designed to operate in harsh environments, withstanding temperatures from -40°C to +70°C, ensuring consistent performance in diverse conditions.

lComprehensive I/O Capacity: Equipped with 28 digital inputs, 8 analog inputs, and 16 digital outputs, providing extensive monitoring and control capabilities

Conclusion

Selecting the right RTU is crucial for the efficiency, reliability, and scalability of your power grid automation system. The F-RLY600CR RTU offers a robust and future-ready solution, combining advanced features, modular design, and cybersecurity compliance to meet the evolving demands of modern power grids.

To learn more about the F-RLY600CR RTU and how it can enhance your power grid operations, visit our product page or contact our sales team for personalized consultation.