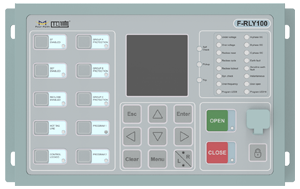

Feeder Terminal Unit F-FTU200

Feeder Terminal Unit F-FTU200

Overview

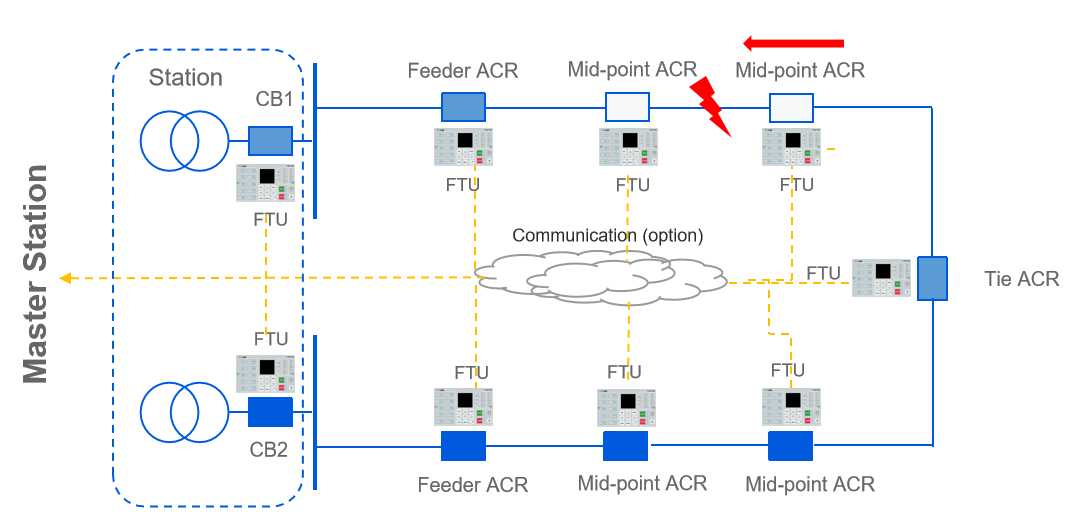

With the continuously development of distribution automation worldwide, more and more Feeder Terminal Units are applied in overhead lines, while protecting feeder, implementing local or centralized fault self-recovery control, and by communication network, and by communication network, connecting to SCADA system, realizing “Tele-signal”, “Tele-measurement”, “Tele-control”, and “Tele-regulating ” function.

In distribution power grid, Feeder Terminal Unit (FTU) is the key point to realize feeder automation. Feeder Terminal Units main function is to realize Fault Detection, Isolation and Restoration (FDIR), reducing outage time, improving reliability of power supply.

Our latest developed F-FTU200 series products can be completed to various pole mounted switches, including Automatic Circuit Recloser (ACR), Circuit Breaker (CB), and can provide a variety of automation solutions to comply with IEC/ANSI international standards.

Feature and Benefit

-

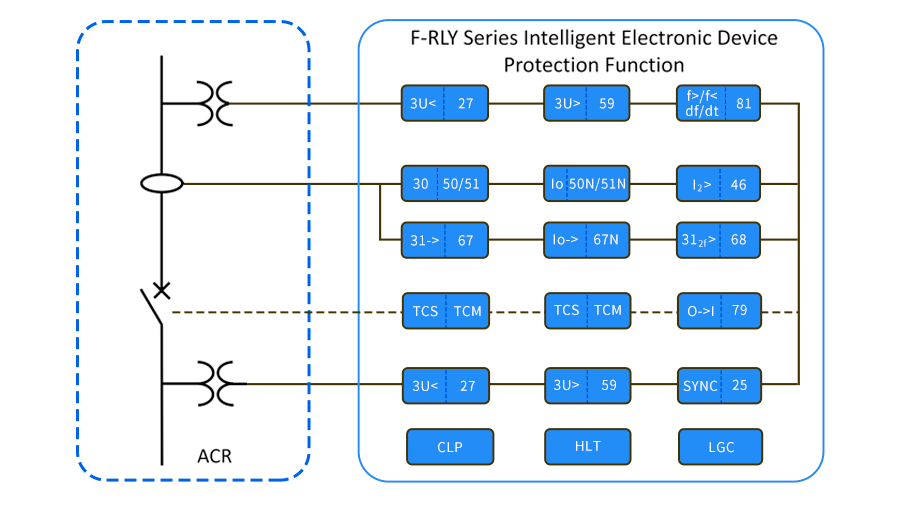

Multiple Protection

Support definite time curve, 26 l inverse definite minimum time curves, 24 user-defined curves, comply with IEC and ANSI standards, and satisfied with diverse needs of customers.

-

Distribution Automation

Realize feeder automation, support loop automation and auto-changeover solutions of the recloser, and satisfy with demands of Fault Detection, Isolation and Restoration (FDIR).

-

Multiple Protocols

Support IEC 60780-5-101/104,DNP3.0 and MODBUS standard protocols, supports protocol synchronization and B code time synchronization functions, and satisfy the needs of customers for “Tele- signal”, “Tele-measurement”, “Tele-control”, and “Tele-regulating ”.

-

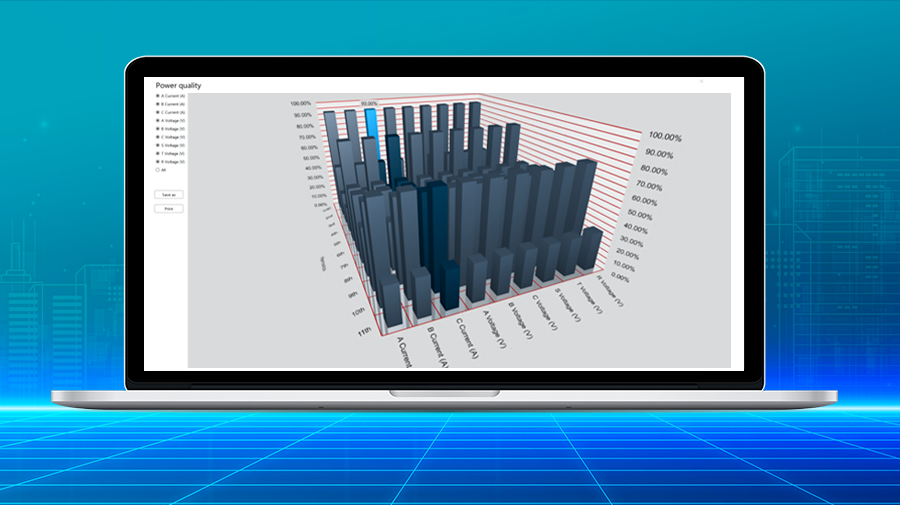

Power Quality Analysis

Support power quality analysis, you can check the proportion of harmonic components of up to 16 analog quantity in real time, including current, voltage, active power, reactive power, apparent power, and up to 11 harmonics can be calculated to meet Customers’ high-quality electricity demands.

-

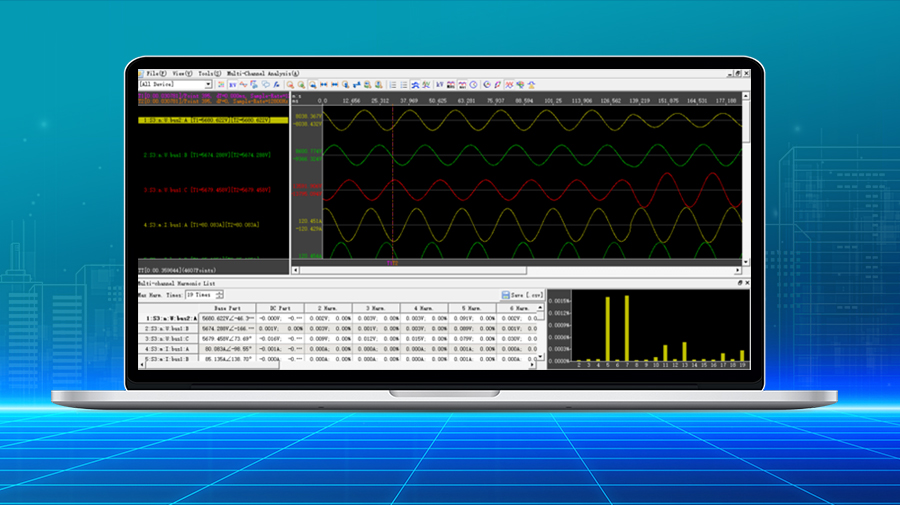

Waveform Capture

Support record 10 fault records with a maximum of 10 seconds at the storage rate of 128 sampling points in each fundamental frequency period, and store up to 100 fault wave-forms to help customers comprehensively analyze the reason of the fault, tracing the rooting cause to solve the problem.

-

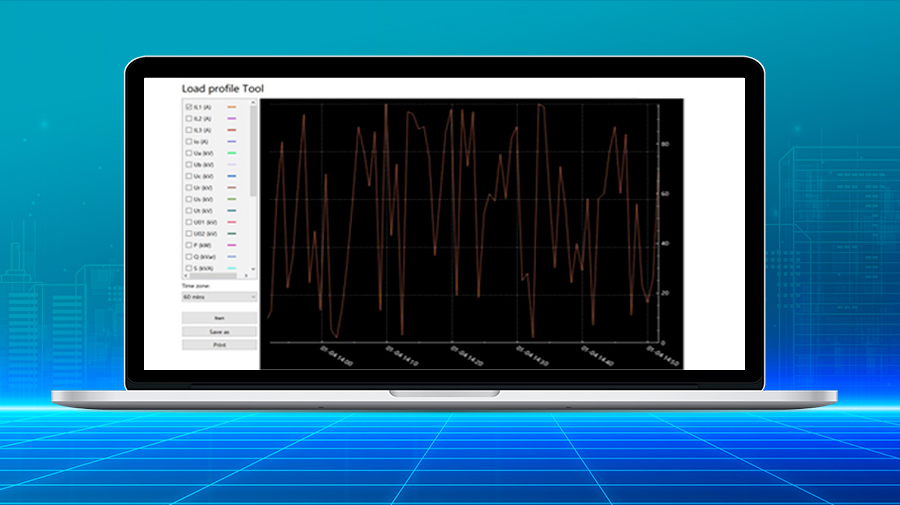

Load Profile

Support load profile function, you can check the historical data curve of 10 analog quantities, the minimum time scale is 1 minute, and can backtrack the historical data of up to 30 days, which is convenient for customers to track and save the data.

Technical Parameter

Technical Description:

| Parameter | F-FTU200 |

| Power suppy range | 100 … 240 V AC |

| Maximum power consumption | <30 W |

| Duration of operation without auxiliary supply | 24H |

| Rated frequency | 50/60 Hz |

| Operation voltage | 24 V DC (20 … 29 V DC ) |

| Rechargeable battery type | Sealed lead acid |

| Rechargeable battery voltage & capacity | 2*12V/12AH |

| Analog input | 4I+6Us |

| Current transformer input ratio | 1/5A |

| Voltage sensor input range | 0~8V rms |

| Binary input/output | 10 BI/4BO |

| Binary output breaking capacity (at L/R=40ms) | 30W |

| RTD/mA inputs | 4~20mA |

| Debugging port on front panel | RJ45 Ethernet port |

| Communication serial port on rear panel | RS232 & RS232/485 serial port |

| Communication ethernet port on rear panel | RJ45 Ethernet port |

| Communication protocol | IEC101/104, DNP3.0, MODBUS |

| Temperature range | -25°C ... +70°C |

| Degree of protection | IP55 |

| Dimension | 836*445*330 mm |

| Space room for radio | 210*180*130 mm |

| Weight | 60kg |