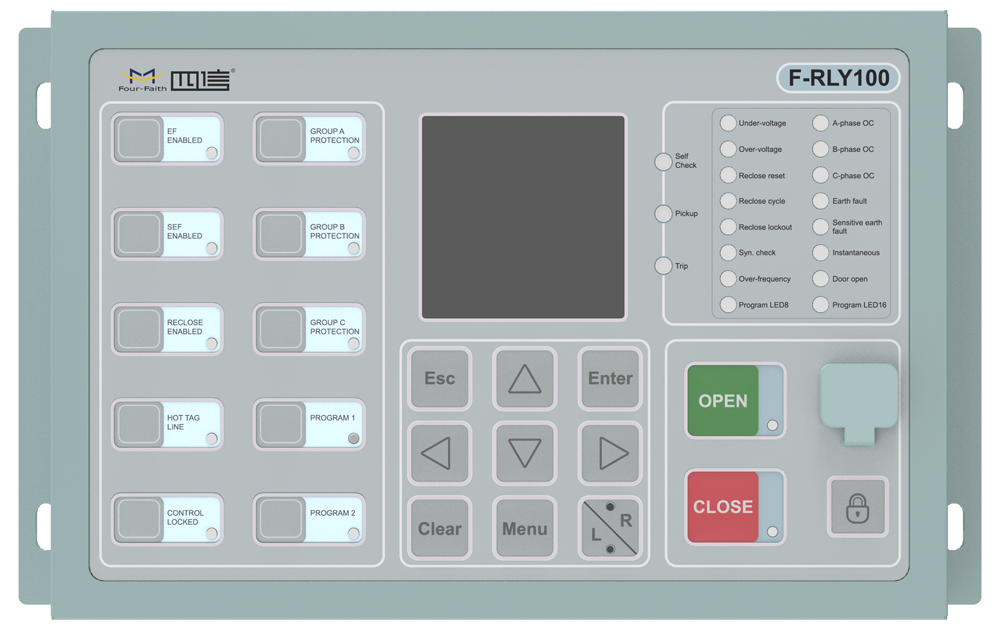

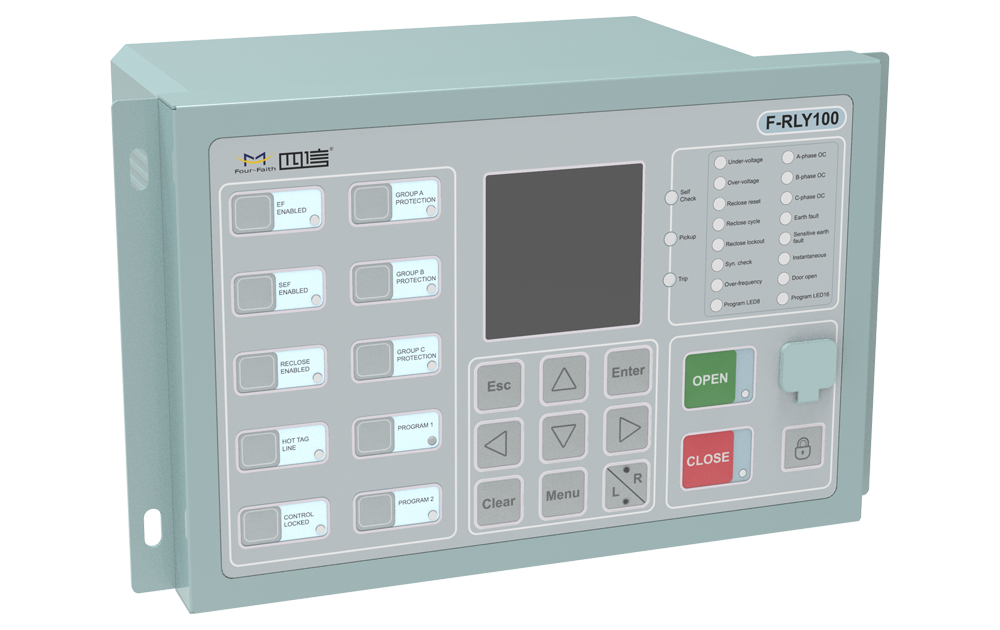

Feeder Protection Relay F-RLY100

Feeder Protection Relay F-RLY100

Overview

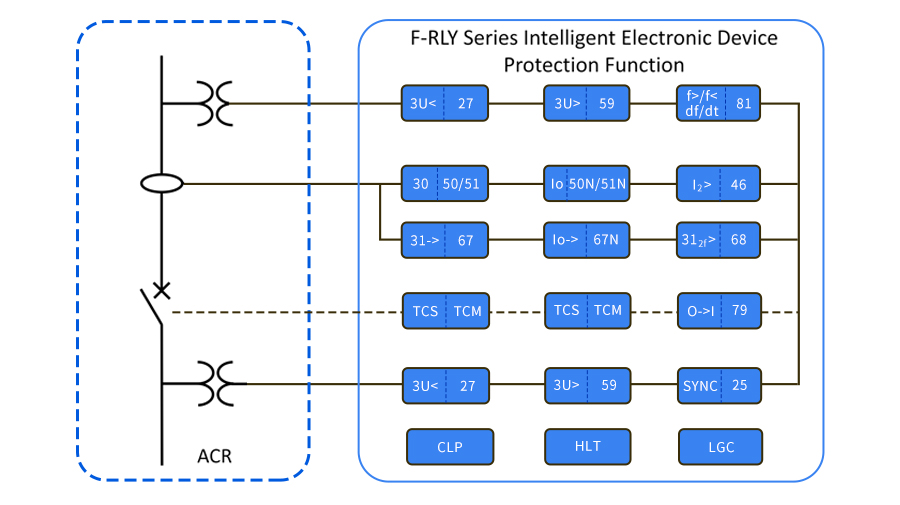

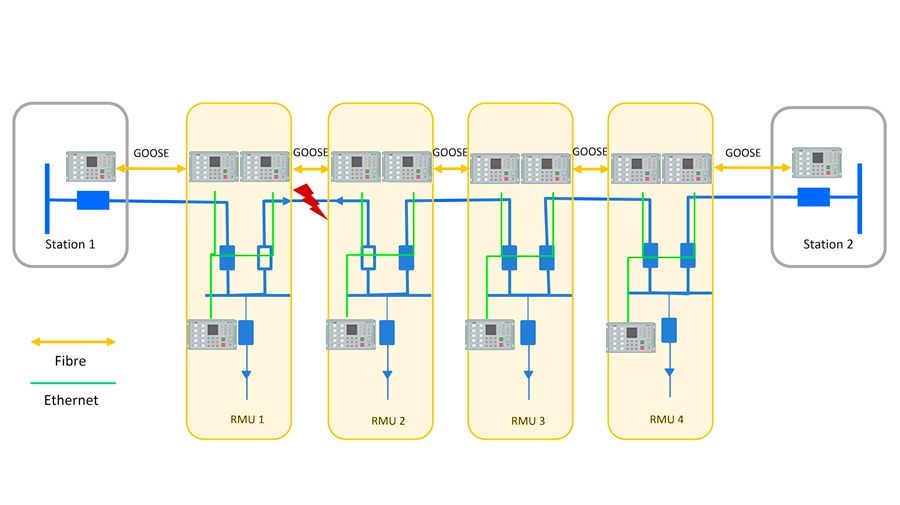

Feeder protection relays are mainly used in overhead lines and cable lines, and are the core components of Feeder Terminal Units (FTU), Ring Main Units (RMU), and Primary Switch-gears (PSG), with the functions of protection, control, measurement, communication, data processing, power management, etc. Feeder protection relays can be configured with a variety of distribution automation logic to realize fault detection, isolation and restoration (FDIR) of feeders, thus reducing outage time, improving power supply reliability, and helping the intelligent upgrading and transformation development of distribution networks.

Feeder protection relays support the substation IEC61850 communication standard, covers horizontal communication, including GOOSE messages with switching signal and analog signal. Feeder protection relays also supports DNP3 (TCP/IP),IEC 60870-5-104/101, and Modbus communication protocols, providing seamless connection to various substations and SCADA systems.

Our lasted developed F-RLY series feeder protection relays with complete functions can be matched with indoor and outdoor primary equipment, and can provide customers with a variety of automation solutions, complying with IEC/ANSI international standards.

Feature and Benefit

-

Multiple Protection

Support definite time curve, 26 l inverse definite minimum time curves, 24 user-defined curves, comply with IEC and ANSI standards, and satisfied with diverse needs of customers.

-

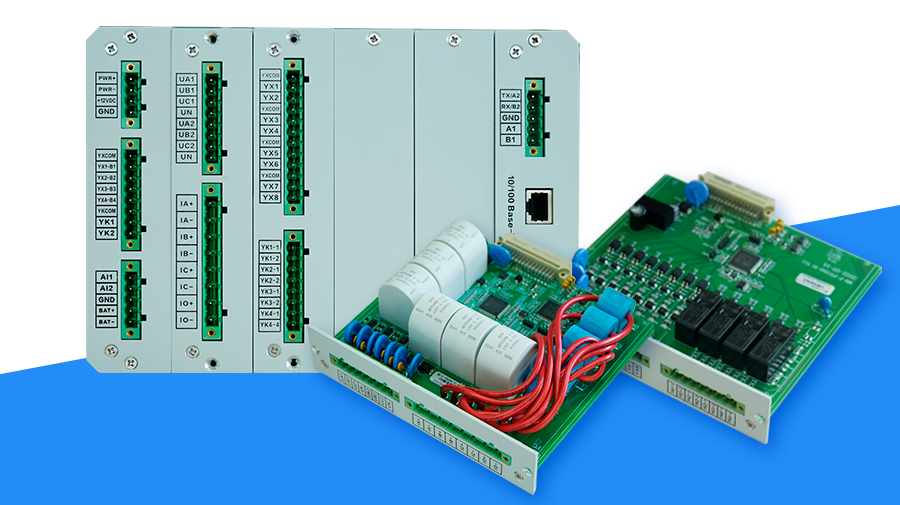

Modular Design

With modular design, power supply, control, measurement and communication are realized by independent cards separately, which is conducive to the extension and replacement of cards at customer sites, saving customer's costs and maintenance time.

-

Rapid Self-Healing

A variety of intelligent distributed network solutions can be realized without relying on the master system, which is applicable to various network topology, and enables the grid to self-heal in milliseconds, meeting customers' demand for a grid with higher stability and reliability.

-

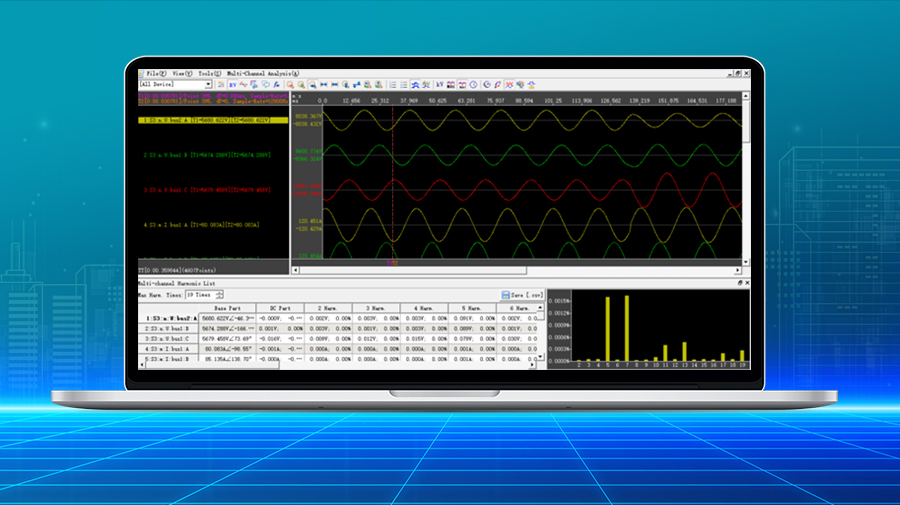

Waveform Capture

Support record 10 fault records with a maximum of 10 seconds at the storage rate of 128 sampling points in each fundamental frequency period, and store up to 100 fault wave-forms to help customers comprehensively analyze the reason of the fault, tracing the rooting cause to solve the problem.

Technical Parameter

Technical Description:

| Parameter/Type | F-RLY100 |

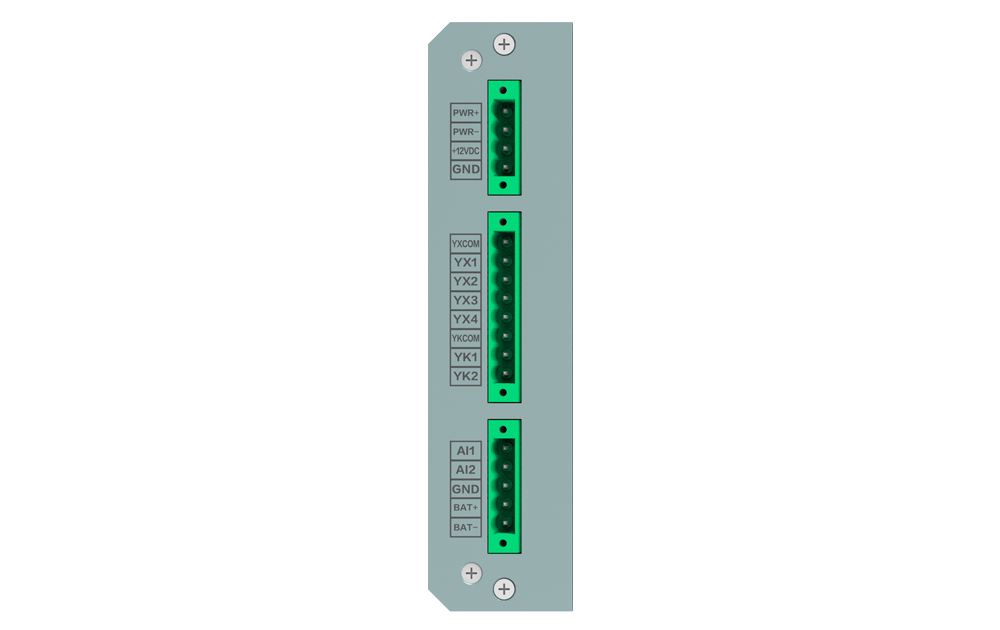

| Power Supply | 20Vdc~29Vdc |

| Voltage Input | 0~4Vac |

| Current Input | 1A/5A |

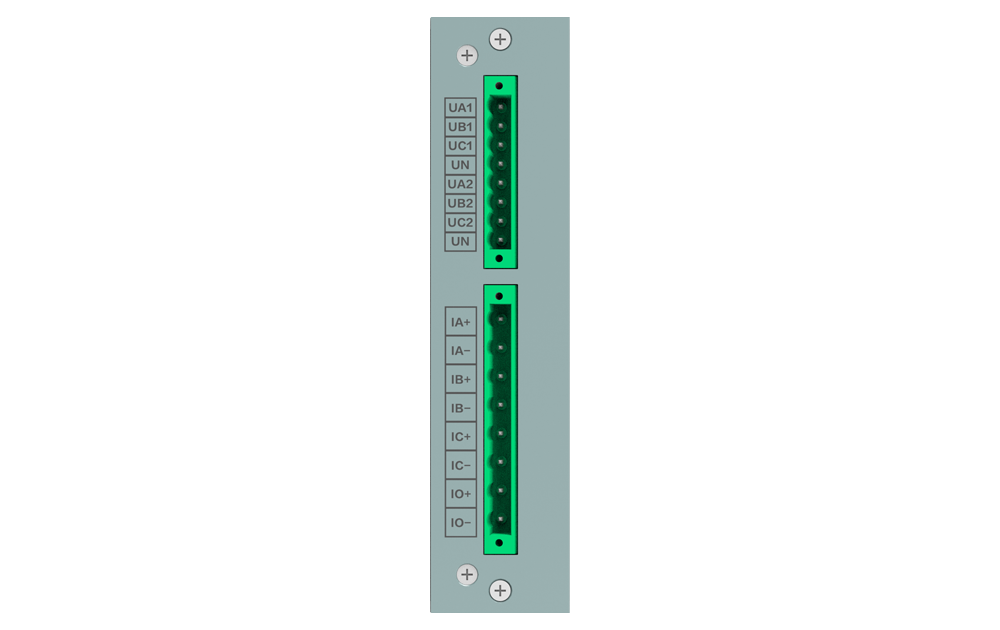

| Analog Input | 3I+Io+6Us |

| Binary Input | 8 channels |

| Binary Output | 4 channels |

| Communication Port | 1*RS232/RS485, 1*RS232, 1*RJ45 |

| Communication Protocol | 101/104/DNP3.0/Modbus |

| LCD Size | 10x20 characters |

| IP Class | Front Panel: IP54; Rear Panel: IP20 |