News

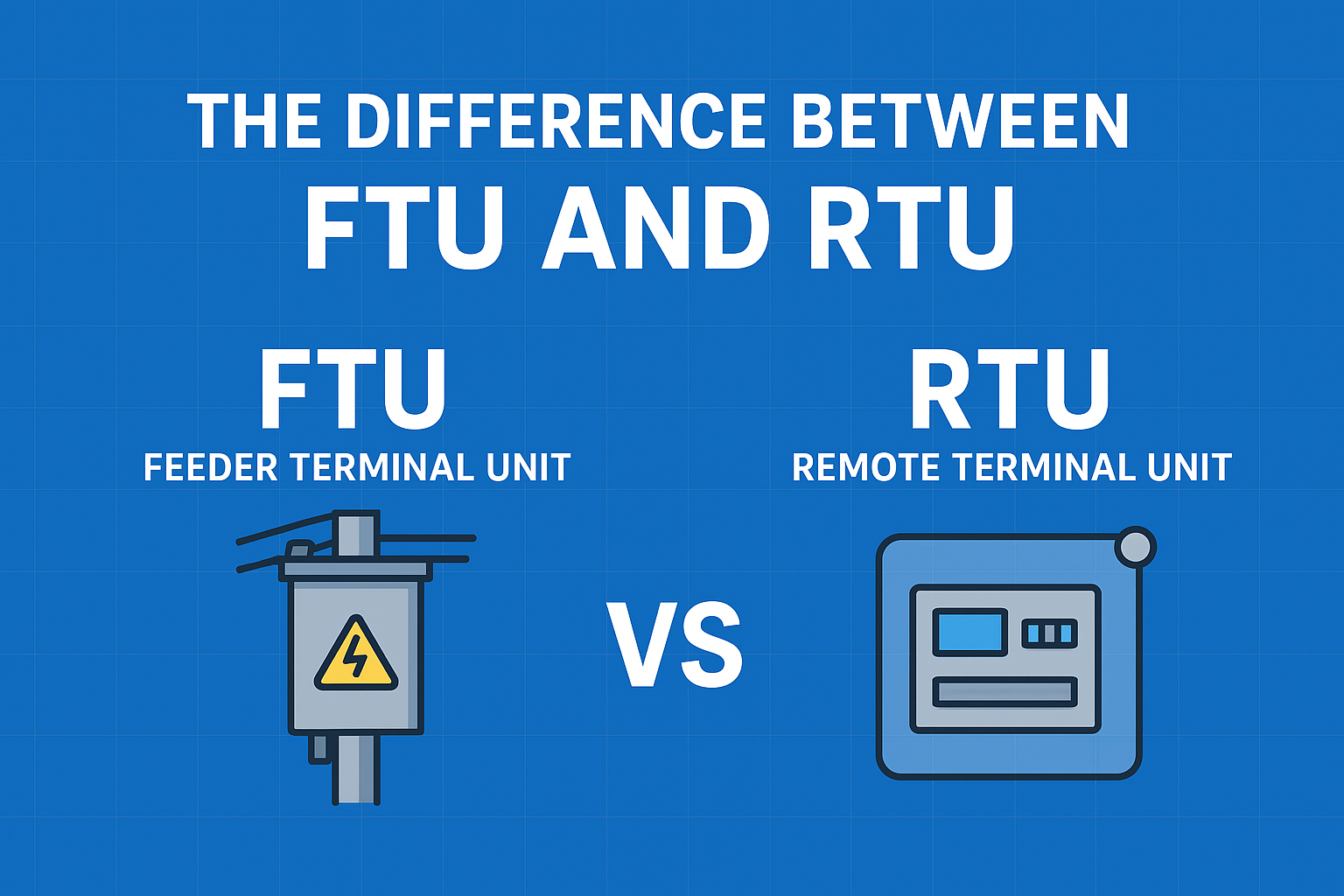

The different between FTU and RTU

Date:2025-12-11

FTU (Feeder Terminal Unit) is a specialized type of RTU (Remote Terminal Unit) focused on monitoring and controlling individual power feeder switches (like breakers on 10kV lines) for fault detection and automation, while an RTU is a broader, more versatile device for general remote data acquisition and control of various industrial assets, acting as the bridge to a central SCADA system. Think of FTU as a dedicated feeder expert, and RTU as the general field controller, with FTUs often being integrated into the larger RTU framework or performing RTU-like functions for feeders.

FTU (Feeder Terminal Unit)

Focus:

Specific to electrical distribution feeders (lines from substations).

Function:

Monitors and controls feeder switches (breakers, load switches, etc.), measures three-phase parameters, detects faults, and executes remote commands for feeder automation.

Location:

Installed near the switches on the feeders, often pole-mounted.

Key Role:

Automates fault isolation and restoration on feeders.

Focus:

General purpose for various industrial sites and equipment.

Function:

Collects data, monitors, and controls a wide range of field devices (transformers, pumps, etc.) and transmits telemetry to SCADA.

Location:

Can be anywhere in the field, from substations to remote sites.

Key Role:

The primary interface for remote monitoring and control in SCADA systems, with strong communication and environmental resilience.

Key Differences

Scope:

FTU is specialized for feeders; RTU is general purpose for overall system control.

Functionality:

FTU is geared towards feeder protection and automation; RTU handles broader telemetry and control.

Relationship:

An FTU can be considered a specialized form or component within a larger RTU-based distribution automation system, often communicating with the main RTU or master station.