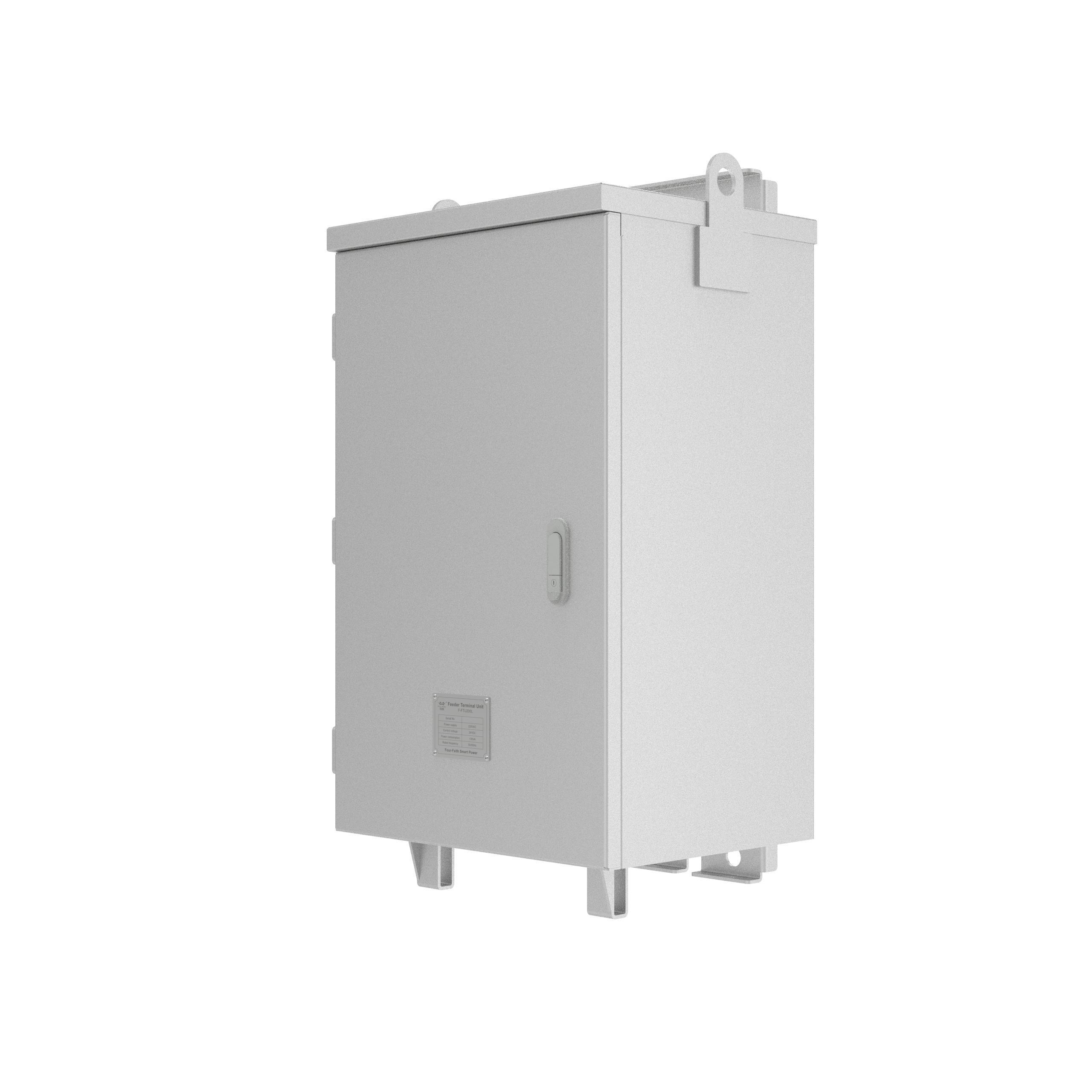

Feeder Terminal Unit F-FTU200L

Feeder Terminal Unit F-FTU200L

Overview

The F-FTU200L is a microprocessor-based controller designed for LBS(Load Break Switch)/SEC (Sectionalizer) applications in distribution automation. It provides fault detection, protection, remote control, measurement, and communication functions in one compact unit.

The device supports IEC and ANSI protection curves and allows easy setting and coordination. Housed in a weatherproof cabinet, the F-FTU200L ensures reliable operation in outdoor environments, enabling fast fault isolation and restoration for improved power system performance.

Feature and Benefit

-

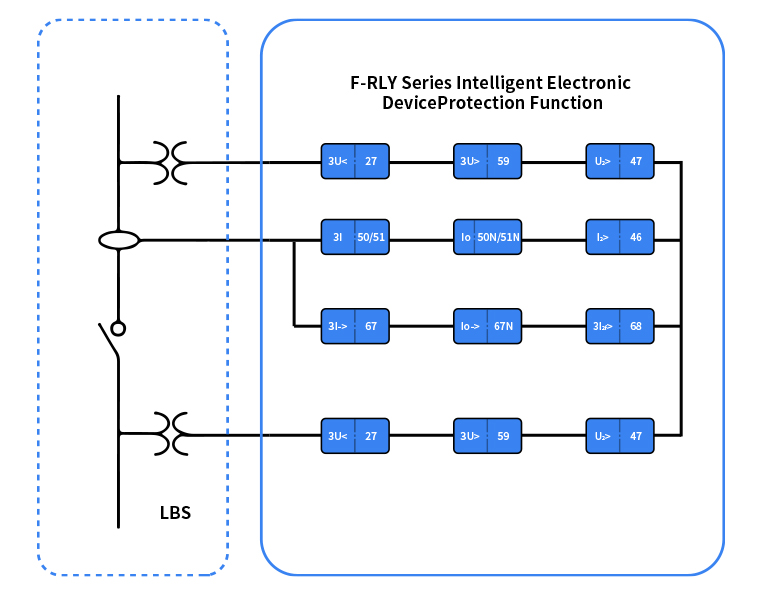

Multiple Protection

Realize multiple protection functions for overhead lines, support definite time curve, 26 l inverse definite minimum time curves, 24 user-defined curves, comply with IEC and ANSI standards, and satisfied with diverse needs of customers.

-

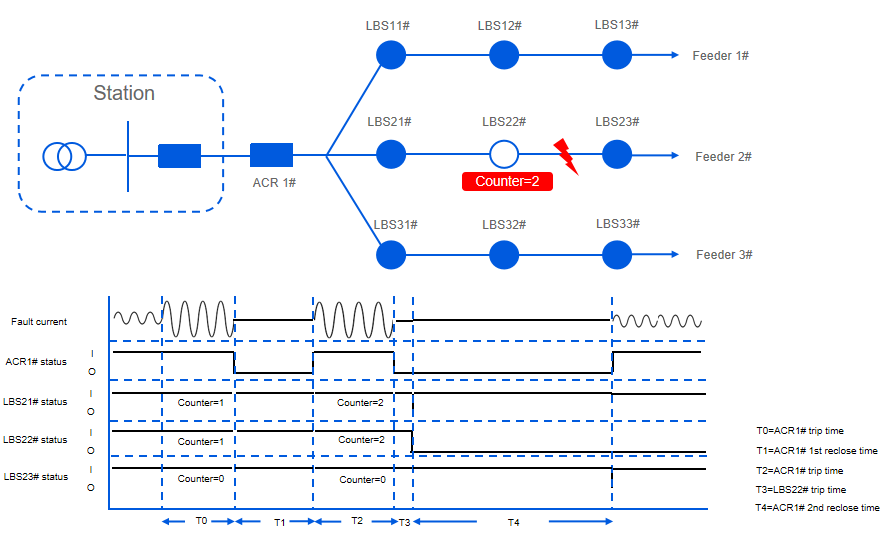

Distribution Automation

Realize feeder automation, support current-based and voltage-based solutions of the sectionalizer, and satisfy with demands of Fault Detection, Isolation and Restoration (FDIR).

-

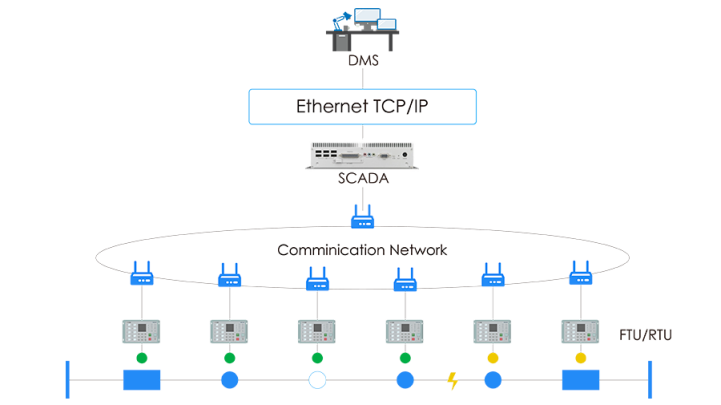

Multiple Protocol

Support IEC 60780-5-101/104,DNP3.0 and MODBUS standard protocols, supports protocol synchronization and B code time synchronization functions, and satisfy the needs of customers for “remote signal”, “remote measurement”, “remote control”, and “remote regulating

-

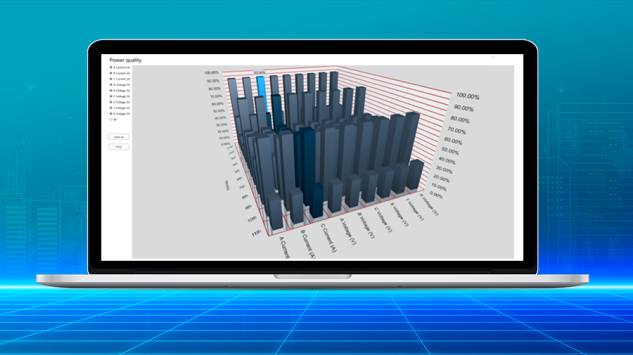

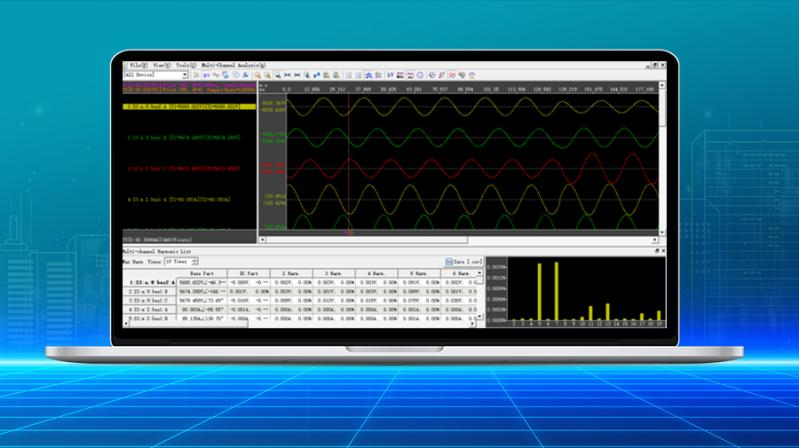

Power Quality Analysis

Support power quality analysis, you can check the proportion of harmonic components of up to 16 analog quantity in real time, including current, voltage, active power, reactive power, apparent power, and up to 11 harmonics can be calculated to meet Customers’ high-quality electricity

-

Waveform Capture

Support 10 fault records with a maximum of 10 seconds at the storage rate of 128 sampling points in each fundamental frequency period, and store up to 100 fault wave-forms to help customers comprehensively analyze the reason of the fault, tracing the rooting cause to solve the problem.

-

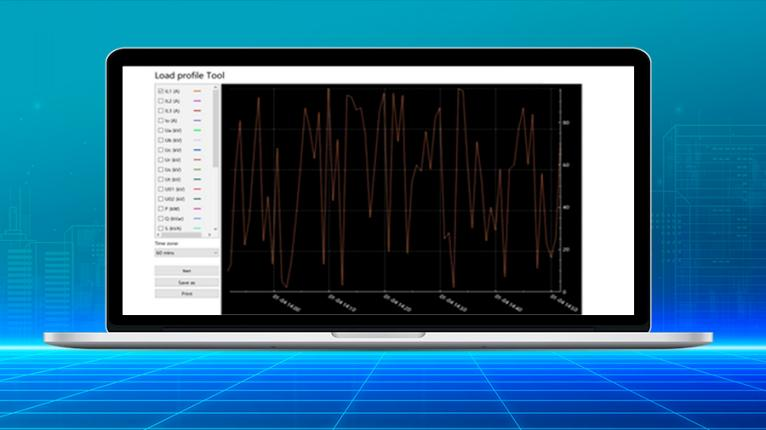

Load Profile

Support load profile function, you can check the historical data curve of 10 analog quantities, the minimum time scale is 1 minute, and can backtrack the historical data of up to 30 days, which is convenient for customers to track and save the data.

Technical Parameter

Technical Description:

| Parameter | F-FTU200L |

| Power suppy range | 100 ··· 240 V AC |

| Maximum power consumption | <30 W |

| Duration of operation without auxiliary supply | 24H |

| Rated frequency | 50/60 Hz |

| Operation voltage | 24 V DC (20···29 V DC ) |

| Rechargeable battery type | Sealed lead acid |

| Rechargeable battery voltage & capacity | 2*12V/12AH |

| Analog input | 4I+6Us |

| Current transformer input ratio | 1/5A |

| Voltage sensor input range | 0~8V rms |

| Binary input/output | 8 BI/4BO |

| Binary output breaking capacity (at L/R=40ms) | 30W |

| RTD/mA inputs | 4~20mA |

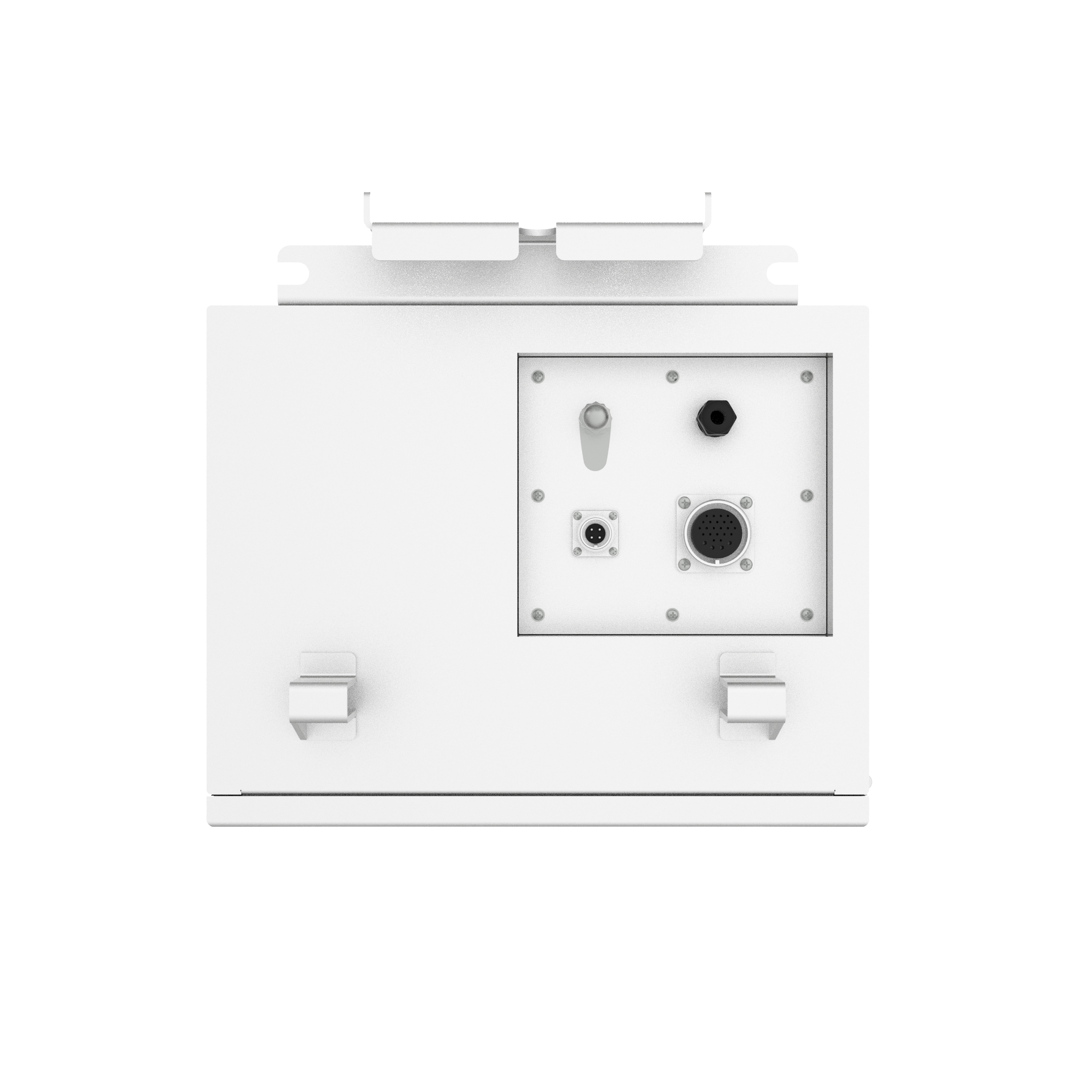

| Debugging port on front panel | RJ45 Ethernet port |

| Communication serial port on rear panel | RS232 & RS232/485 serial port |

| Communication ethernet port on rear panel | RJ45 Ethernet port |

| Communication protocol | IEC101/104, DNP3.0, MODBUS |

| Temperature range | -25°C ···+70°C |

| Degree of protection | IP55 |

| Dimension | 675mm*420mm*330mm |