News

SF6 vs Vacuum Load Break Switches: Key Technical Differences

Date:2025-11-26

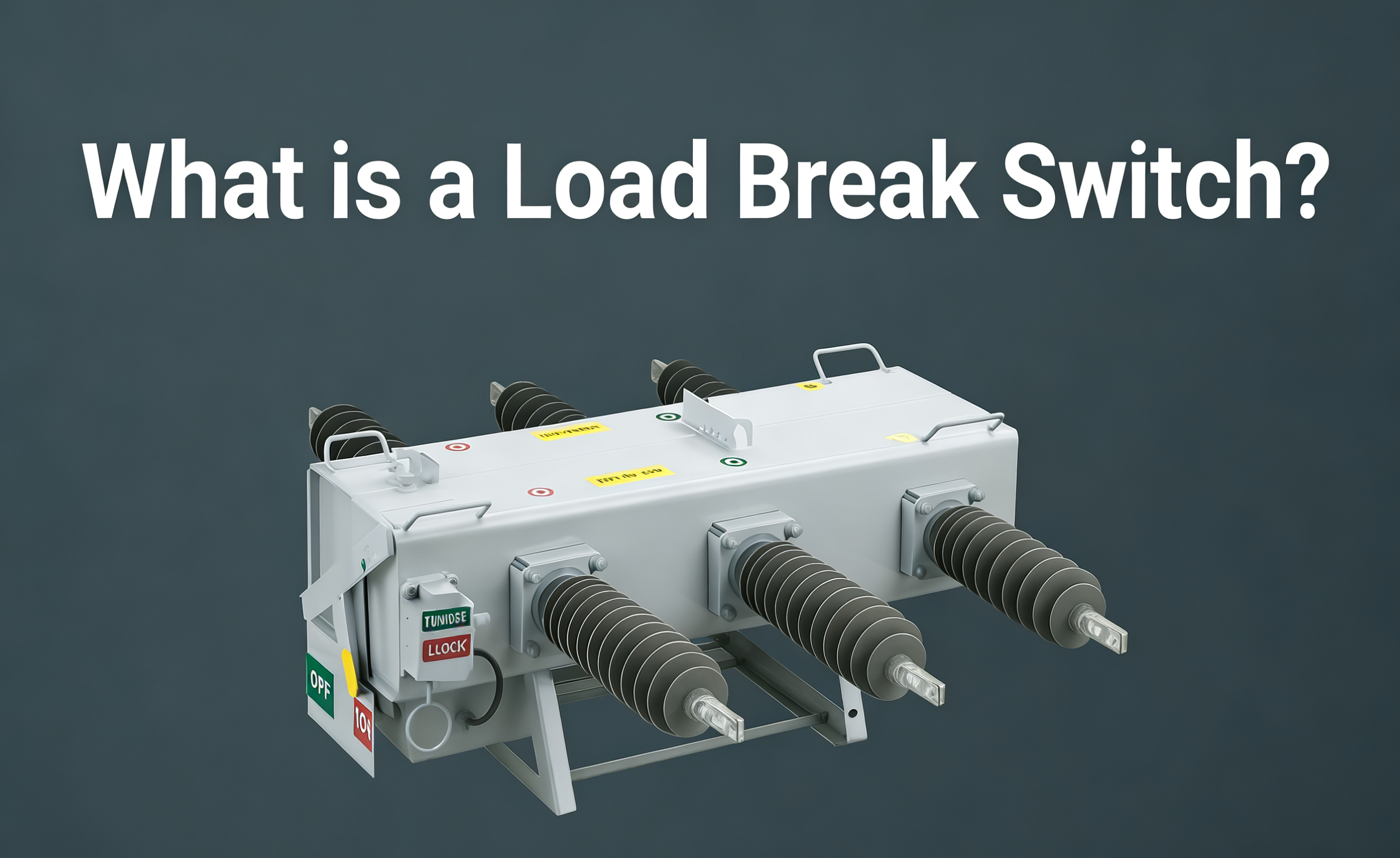

In modern overhead distribution systems, load break switches (LBS) installed on utility poles are crucial for controlling and protecting electrical circuits. Among the available technologies, SF6 (Sulfur Hexafluoride) and Vacuum interrupters represent the two dominant solutions. Understanding their differences is key for utility engineers and planners.

The Core Technology: Arc Quenching Medium

The primary function of a load break switch is to safely interrupt the flow of current, which involves extinguishing the electric arc that forms when contacts separate. The fundamental difference between the two types lies in their arc quenching medium.

SF6 Load Break Switches: utilize sulfur hexafluoride gas sealed within the interrupter chamber. SF6 is an electronegative gas, meaning it has a high affinity for free electrons. When an arc is drawn, the SF6 gas rapidly absorbs the electrons, forming immobile negative ions. This process effectively de-ionizes the arc path, leading to quick and efficient arc extinction. The arc energy is absorbed and contained within the gas medium. Modern SF6 LBS are typically of the "puffer" type, where the mechanical operation of the switch compresses the gas and blasts it through the arc to ensure rapid quenching.

Vacuum Load Break Switches, as the name implies, house their contacts inside a hermetically sealed vacuum bottle. In a high vacuum (typically 10^-6 to 10^-8 torr), the medium density is extremely low, making it nearly impossible to sustain an arc. When the contacts separate, the minimal metal vapor released from the contact surfaces is ionized to form the arc plasma, which diffuses instantly at the next current zero crossing. The dielectric strength in a vacuum recovers remarkably fast, preventing the arc from re-striking.

Comparative Analysis: Strengths and Weaknesses

Dielectric & Interrupting Performance:

SF6:SF6 gas has excellent dielectric properties, often three times better than air. This allows for a relatively compact interrupter design for a given voltage level. Its interrupting capability is robust and reliable.

Vacuum:A vacuum provides the highest known insulating strength. Vacuum interrupters can handle a high number of interruptions, especially suitable for applications with frequent switching or high inrush currents (e.g., capacitor banks, transformers).

Environmental Impact:

SF6: This is the most significant drawback. SF6 is a potent greenhouse gas with a global warming potential (GWP) 23,500 times that of CO2 over a 100-year period. While the units are sealed-for-life, any leakage during handling, failure, or at end-of-life poses a serious environmental risk. Regulations are increasingly phasing out SF6 in many regions.

Vacuum: Vacuum technology is inherently environmentally benign. There is no gas to leak, and the components are inert and non-polluting. This makes it the clear winner from a sustainability perspective.

Maintenance and Lifecycle:

SF6: The performance is dependent on gas density. Switches often incorporate a pressure gauge for monitoring. A loss of pressure compromises performance and requires immediate attention.

Vacuum: Vacuum bottles are maintenance-free and have a long, predictable service life. Their integrity is typically verified with a simple dielectric withstand test, and they do not require gas monitoring.

Physical Size and Cost:

SF6: Traditionally, SF6 interrupters have been more compact and cost-effective for certain medium-voltage ratings.

Vacuum: Historically, vacuum bottles were bulkier, but advancements have significantly reduced their size. While sometimes slightly higher in initial cost, the total cost of ownership can be lower due to zero gas-related maintenance and environmental compliance costs.

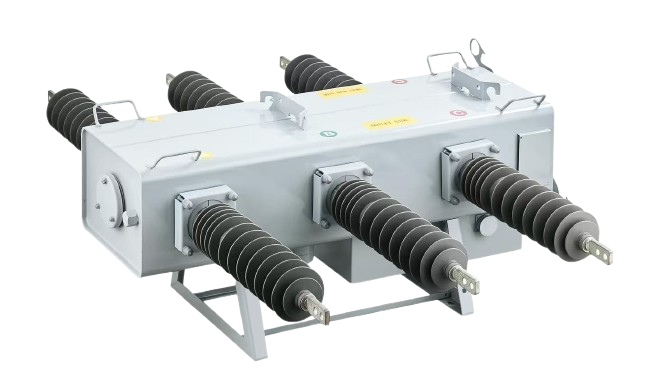

Four-Faith LBS – Designed for Modern Distribution Networks

Four-Faith’s overhead load break switch portfolio includes both SF6 and Vacuum technologies, allowing utilities to choose the ideal solution based on environmental policy, maintenance strategy, and system demands.

Key Features of Four-Faith LBS

- High reliability interrupter technology (available in SF6 and Vacuum)

- Pole-mounted structure optimized for overhead feeders

- Long mechanical and electrical endurance

- Fully sealed and weather-resistant design for harsh outdoor conditions

- Optional automation-ready features, such as:Remote control,Fault detection,Feeder automation integration

Why Four-Faith Stands Out

- Flexible configurations to meet regional utility standards

- Compact, lightweight design simplifying installation

- Advanced insulation and arc suppression design ensuring safe operation

- Compatible with SCADA / Distribution Automation Systems

SF6 & Vacuum Versions Both Available

- SF6 LBS: Stable, mature technology for medium-voltage overhead systems

- Vacuum LBS: Eco-friendly, maintenance-free solution aligned with global SF6 reduction policies

Whether the priority is long-term sustainability, minimal maintenance, or proven interrupting performance, Four-Faith offers a reliable solution tailored for modern grids.

Conclusion: The Industry Trend

Both SF6 and vacuum load break switches are proven and reliable technologies. SF6 switches offer a compact, cost-effective solution with a long track record. However, the overwhelming industry trend is shifting decisively towards vacuum technology. This shift is driven by the urgent need for more environmentally sustainable grid assets and the desire for maintenance-free equipment. For new installations and replacements, vacuum load break switches represent the future-proof, eco-friendly, and operationally simpler choice for modern overhead distribution networks.