Solutions

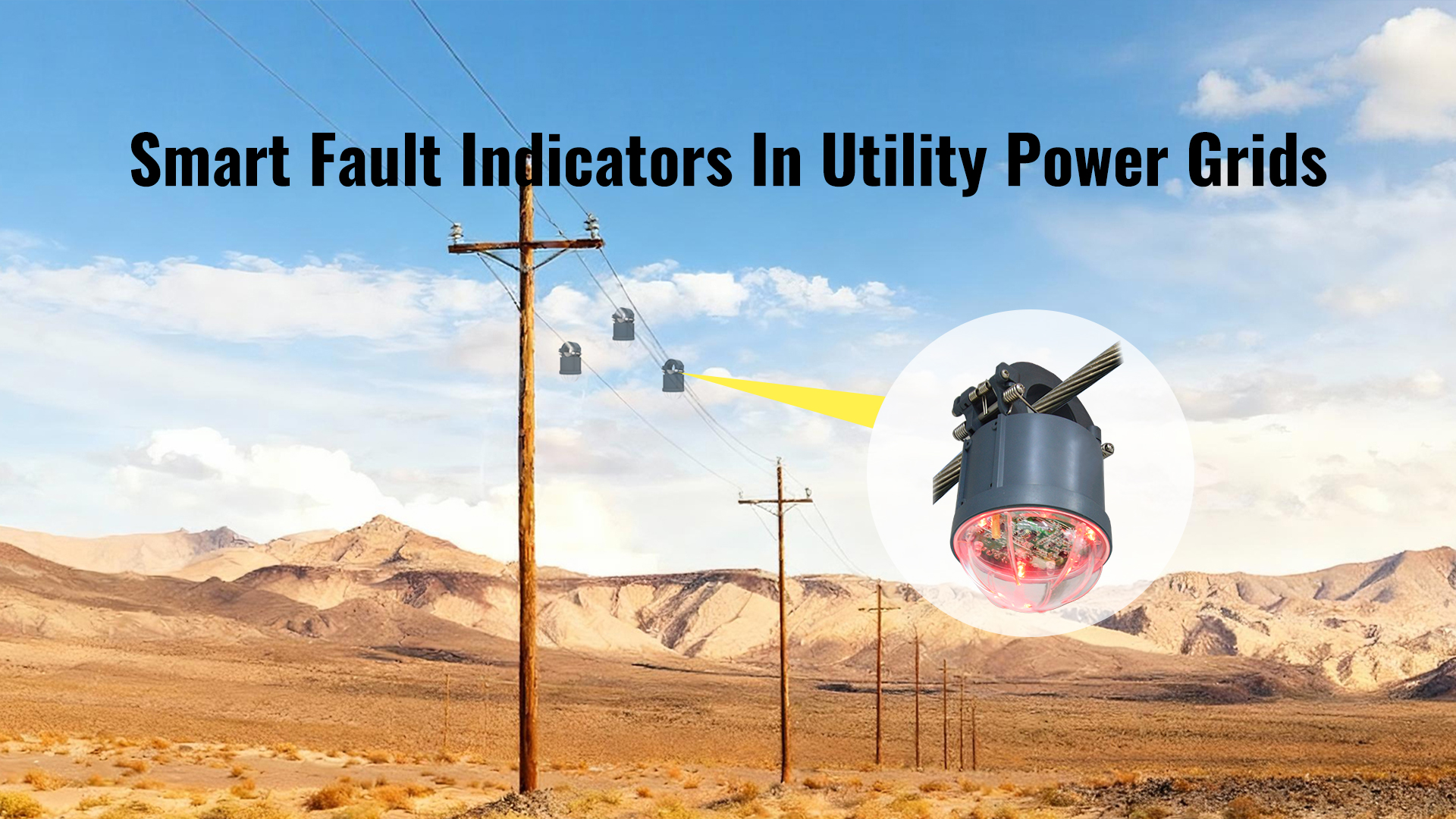

Smart Fault Indicators In Utility Power Grids

Function highlights

Accurate Fault Detection – Identifies short-circuit and ground faults in real time, reducing fault location time from hours to minutes.

Real-Time Data Monitoring – Continuously monitors current, voltage (via electric field), and line temperature for early risk detection.

Wireless Communication – Transmits fault and operation data to SCADA systems through 2G/3G/4G networks.

Live Installation – Enables quick deployment without power interruption or outage.

Smart O&M – Data-driven operation reduces inspection mileage by 80% and labor costs by 50%.

High Integration Capability – Seamlessly connects with existing distribution automation systems.

Enhanced Safety – Minimizes field troubleshooting risks and improves grid reliability.

Overview

Customer Information

ClientName:A power supply company in South America

Industry :Operation and maintenance of public utility power transmission and distribution networks

Scale:Responsible for the operation and maintenance of more than 5,000 kilometers of power distribution lines and 2,000 distribution substations nationwide ; end customers face problems such

as long spans and numerous branches of overhead power lines, vast and sparsely populated areas, long average fault location time of 24-72 hours, frequent unplanned power outages, high labor costs for inspection, and enormous pressure on power supply reliability

Existing operation and maintenance model:

Fault location: Relying on reports from the public and maintenance personnel to conduct seg- mented power outages for troubleshooting, the average location time is as long as 4-8 hours.

Human resources: A large number of inspection teams are needed, on standby 24 hours a day, resulting in high labor costs.

Data gaps: The line's operational status lacks real-time data support, making predictive mainte- nance impossible and relying primarily on passive responses.

Economic and reputational losses: Prolonged power outages lead to high customer complaint rates and cause significant damage to the stable production of local businesses.

Solution introduction

Four - Faith Smart Fault Indicator Solution :

Product Name: JYZ-HW Smart Fault Indicator

Core functions:

1) Precise instantaneous permanent short circuit and ground fault detection and indication (local/re- mote), capable of identifying various line operating conditions such as power outage and resto- ration, and reclosing.

2) Real-time acquisition of line load current, voltage (based on electric field strength), and line temperature.

The line status is transmitted to SCADA in real time via wireless communication ( 2G/3G/ 4G).

3) Independent live installation , eliminating the need for power outages and maintenance.

Deployment plan:

Deployment scale: Approximately [number missing ] were installed on 40 critical paths . 6,000 fault indicators.

Integration and connection with the customer's existing power distribution automation master station system.

Implementation period: From installation to full operation, it takes about 1 year in total.

Feature and Benefit

Core Value: Fault location time was reduced by 85% (from hours to minutes), annual inspection costs were reduced by over 50 % , power outage time was effectively reduced, ensuring normal production for local businesses, and user complaints were significantly reduced.

Quantitative Benefits:

|

Profitability metrics |

Before deployment |

After deployment |

Improvement effect |

Annualized value |

|

Mean Time to Find Fault |

4-8h |

30-60 minutes |

Reduced by approximately 85% |

Save 10,000 hours/year |

|

Fault inspection mileage |

24,000 km/year |

3600km/year |

Reduce by 80% |

Save $ 500,000 /year |

|

Improved human resource efficiency |

10 people/time |

3 people/time |

Reduce by 70% |

|

|

Customer complaint volume |

Approximately 900 times/year |

100 times/year |

Reduced by approximately 88% |

|

Enhanced security: Reduces the risk of maintenance personnel blindly troubleshooting line security issues.

Decision support: Real-time data-driven power grid status awareness provides a basis for network optimization and investment planning.

Brand Image: To build an Smart and highly reliable power distribution network and become an industry benchmark.