Feeder Protection Relay F-RLY200

Feeder Protection Relay F-RLY200

Overview

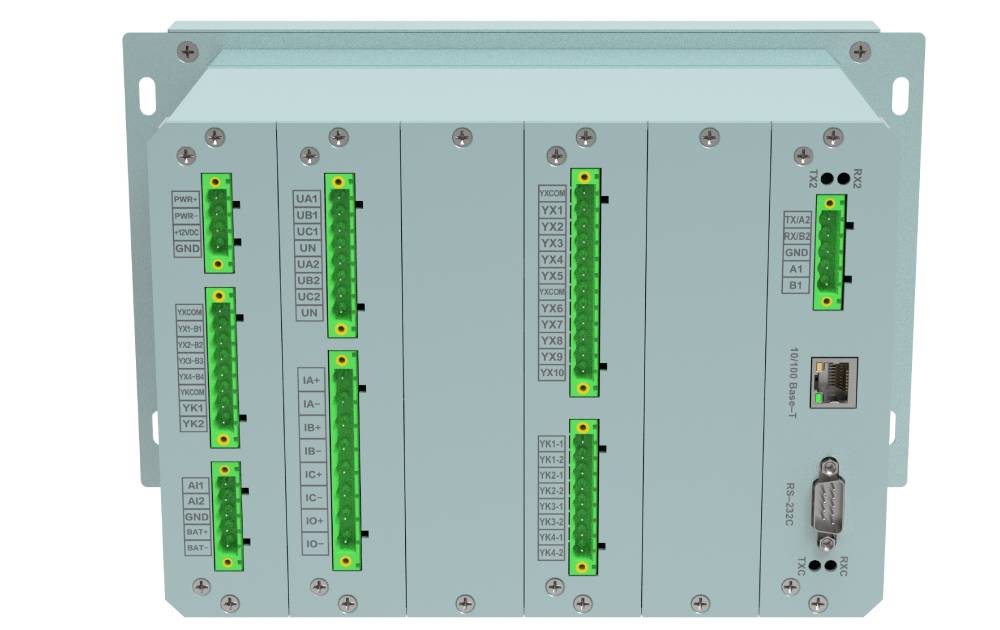

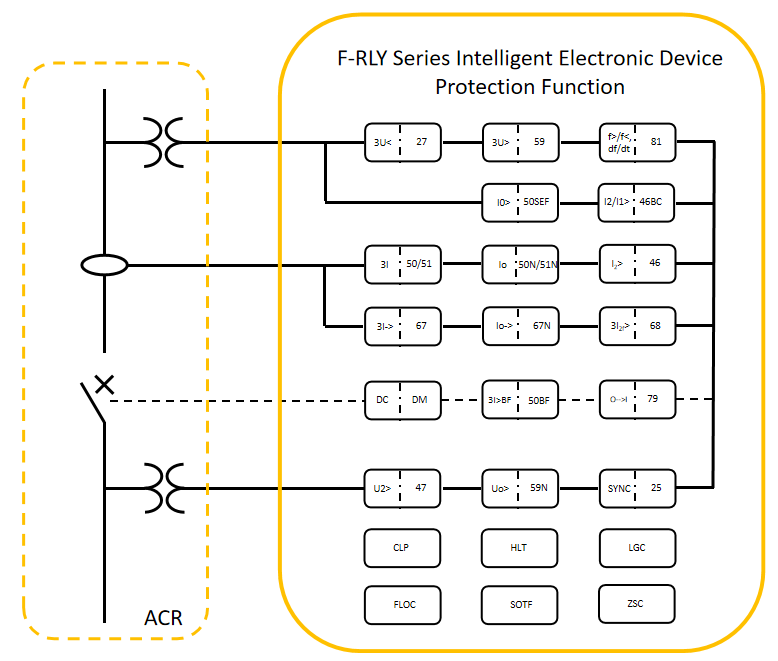

The F-RLY200 is a fully digitalized and microprocessor-based control device which designed to provide protective coordination and fault clearance of distribution systems for the continuous best quality of electric service. It combines protection, measurement, monitoring, control, communication, data handling, and distribution automation in one unit.

Supporting DT, IDMT and user defined curves according to IEC and ANSI standards to provide fully protective coordination for the continuous best quality of electric distribution. Users can select any time of current curve simply by programming and modifying.

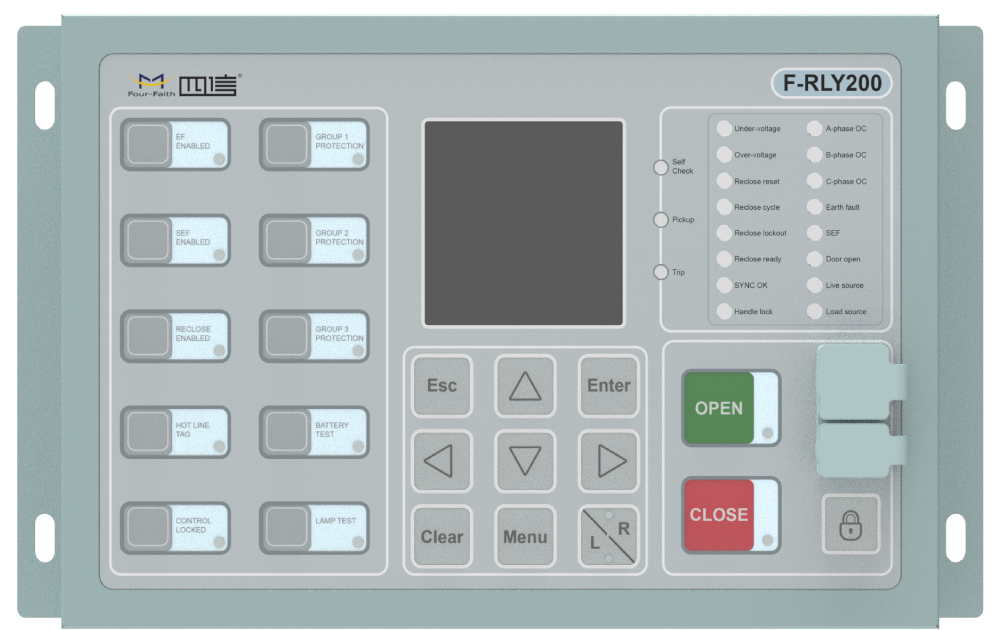

The relay supports Close, Open, and other operations via key buttons on the user interface panel, including Local/Remote, EF Enabled, SEF Enabled, Reclose Enabled, Control Locked, Alternate Settings, Hot Line Tag, Battery Test, Lamp Test, and Authorization. It can also be managed through software on a portable PC for setting modifications, event data acquisition, and operation history management.

Feature and Benefit

-

Powerful Protection

Realize multiple protection functions for overhead lines, support definite time (DT) curve, 28 quantities of inverse definite minimum time (IDMT) curves, and user-defined curves, comply with IEC and ANSI standards, and satisfied with diverse needs of customers

-

Modular Designation

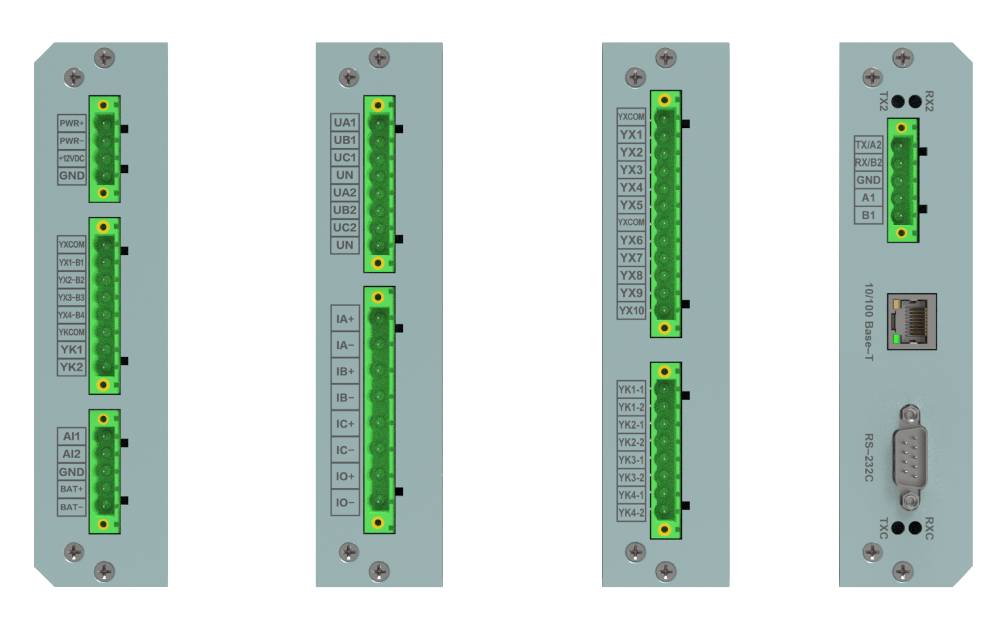

With modular design, power supply, control, measurement and communication are realized by independent cards separately, which is conductive to the extension and replacement of cards at customer sites, saving customer’s costs and maintenance time.

-

Support Fault Records

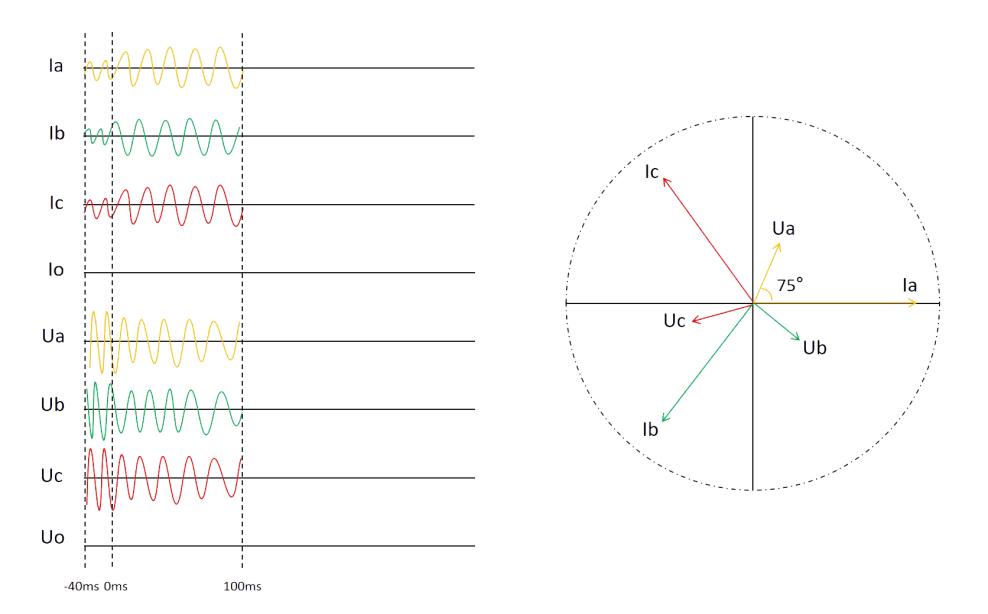

Support fault records function, can record 10 fault records with a maximum of 10 seconds at the storage rate of 128 sampling points in each fundamental frequency period, and store up to 100 fault wave-forms to help customers comprehensively analyze the reason of the fault, tracing the rooting cause to solve the problem.

-

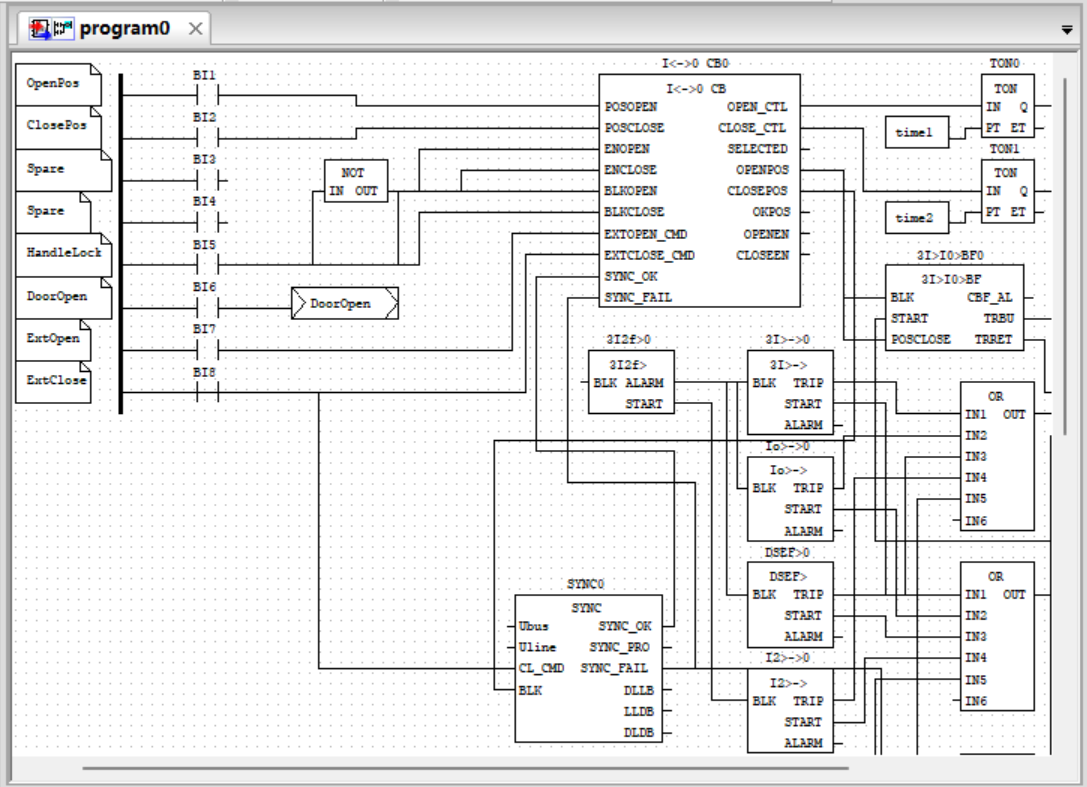

Programmable Logic

Programmable logic builds up functions by using input, output, protection and control block diagram, and is used to perform logic desired by users. Through programmable logic tool, various functions such as signal input, command output, DA solution, inter-lock, programmable LED can be accomplished. Programmable logic is according to IEC 61131-3 standard.

-

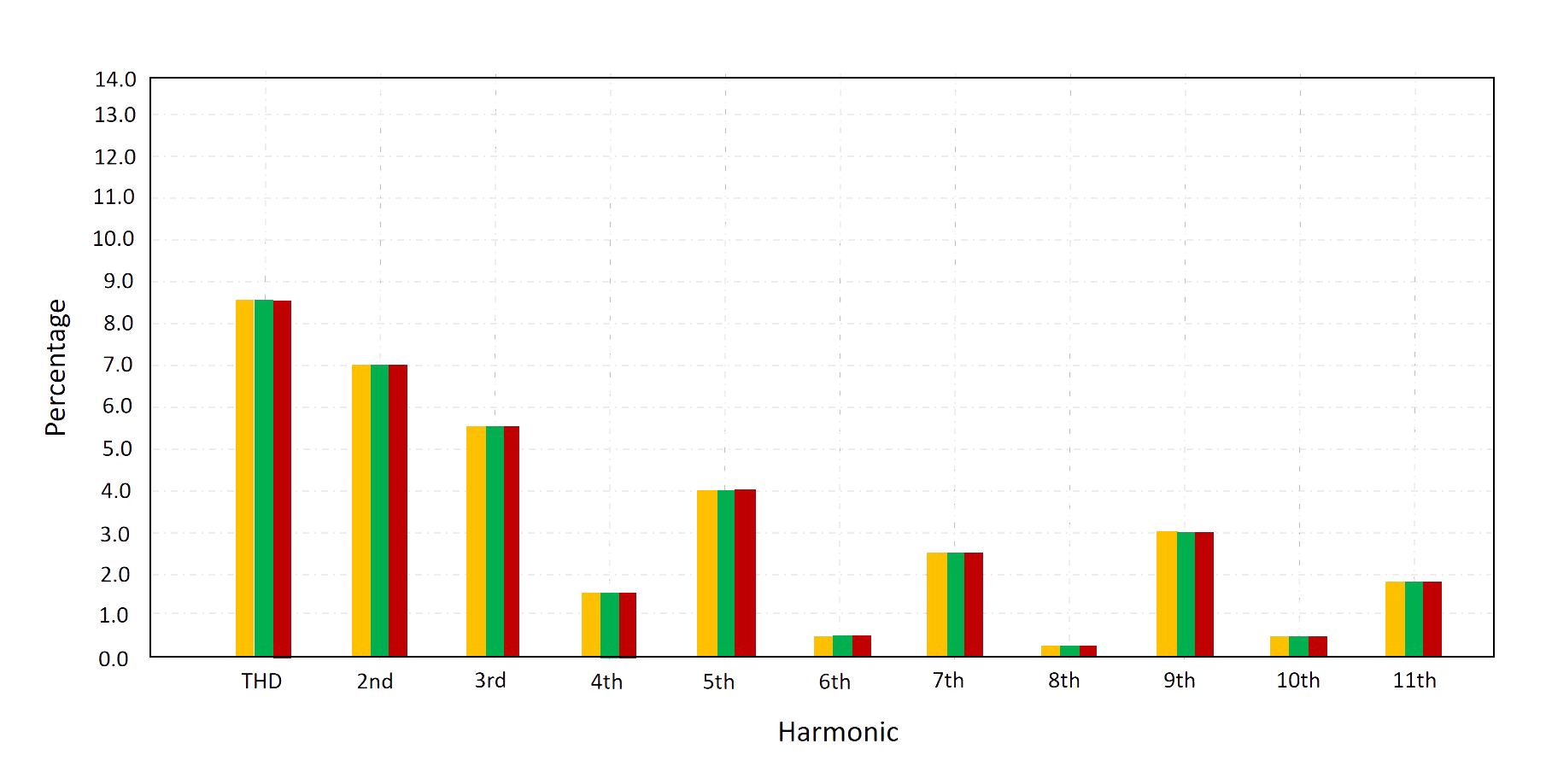

Support Power Quality Analysis

Support power quality analysis, you can check the proportion of harmonic components of up to 16 analog quantity in real time, including current, voltage, active power, reactive power, apparent power, and up to 11 harmonics can be calculated to meet Customers’ high-quality electricity demands.

-

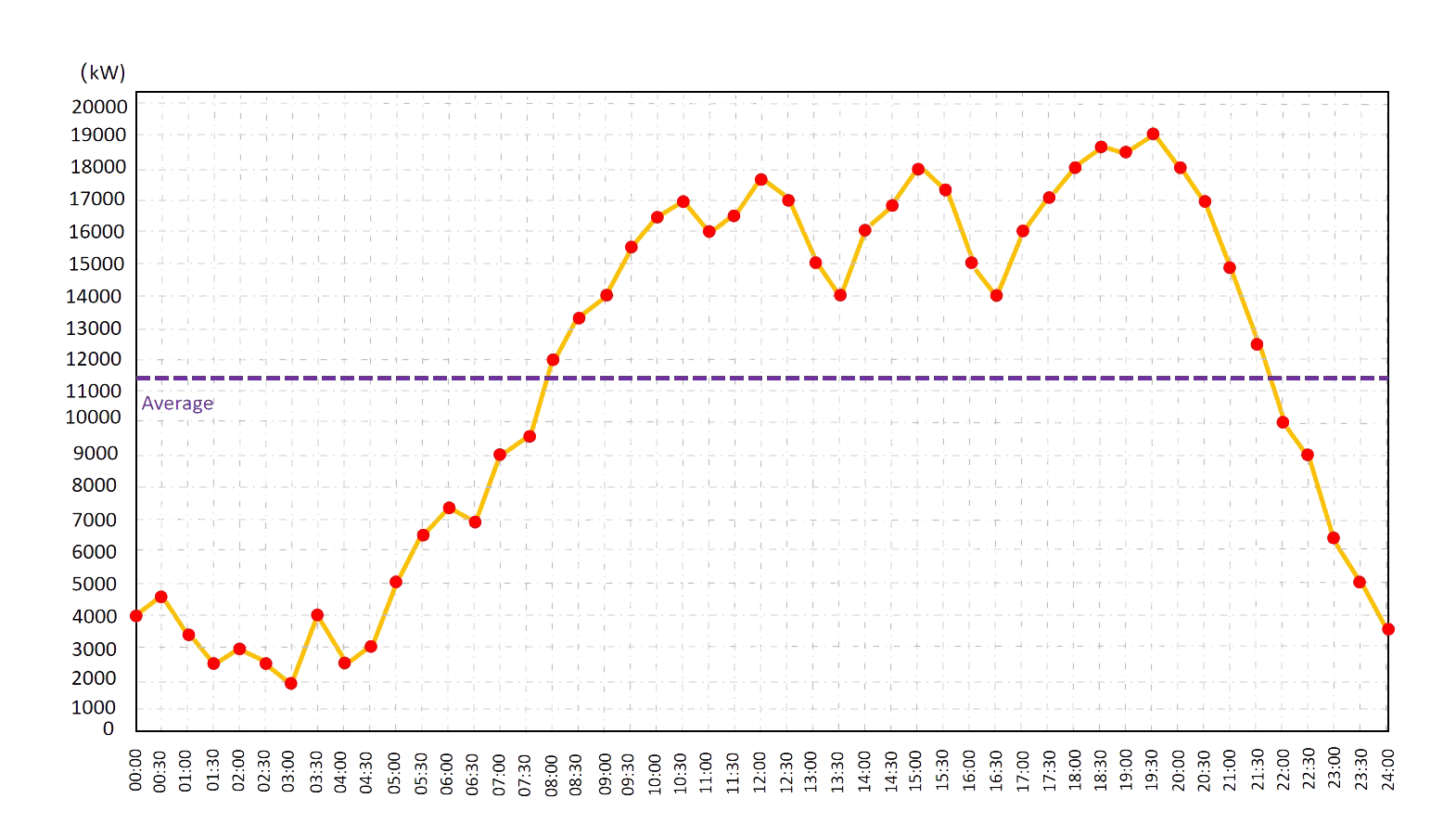

Support Load Profile Function

Support load profile function, you can check the historical data curve of 10 analog quantities, the minimum time scale is 1 minute, and can backtrack the historical data of up to 30 days, which is convenient for customers to track and save the data.

Technical Parameter

Technical Description:

|

Parameter

|

F-RLY200 |

| Power suppy range | 24 V DC (18 … 29 VDC) |

| Maximum power consumption | <10 W |

| Rated frequency | 50/60 Hz |

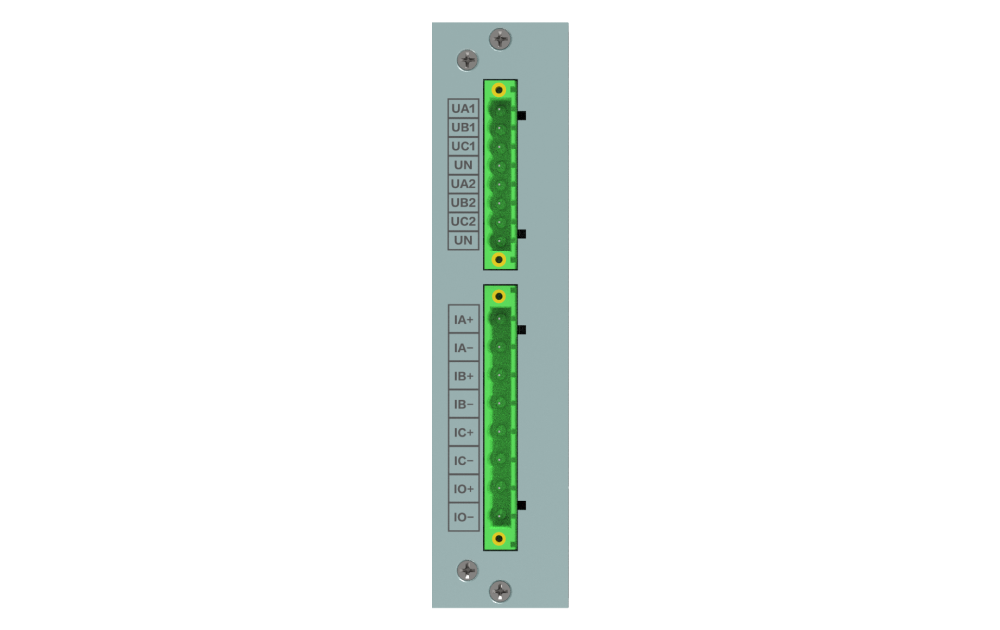

| Analog input | 4I+6Us |

| Current transformer input ratio |

|

| Voltage sensor input range | 0~8V rms(input is optimized with secondary rated phase voltage 4Vrms) |

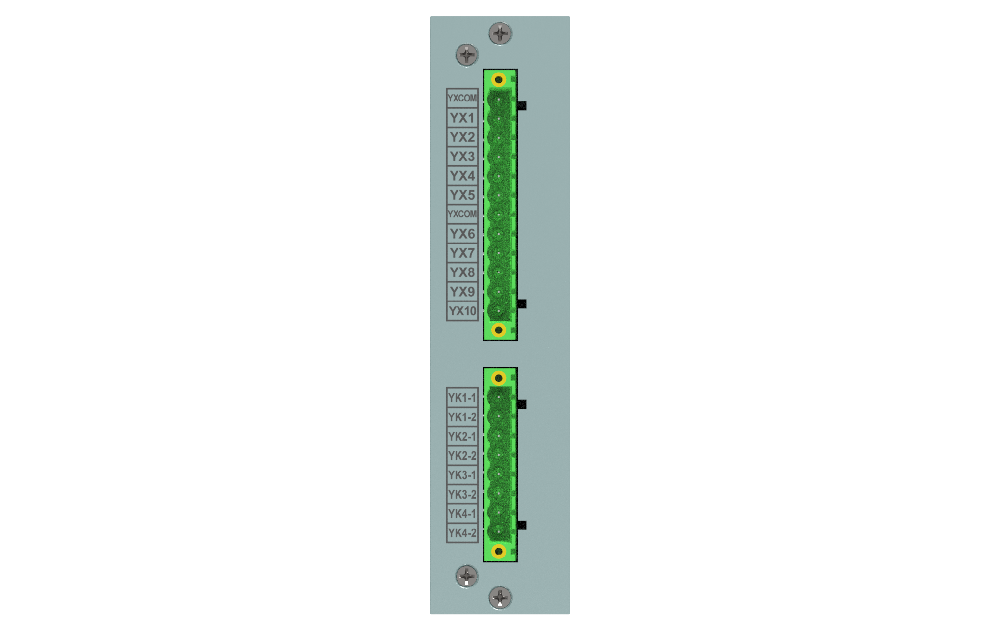

| Binary input/output |

|

| Binary input rated voltage | 24 V DC |

| Binary input threshold voltage | >18 V DC |

| Binary input reaction time | <20 ms |

|

Binary output rated voltage

|

250 V AC |

| RTD/mA inputs | 4-20mA |

| Debugging port on front panel | RJ45 Ethemet port / USB Type B port |

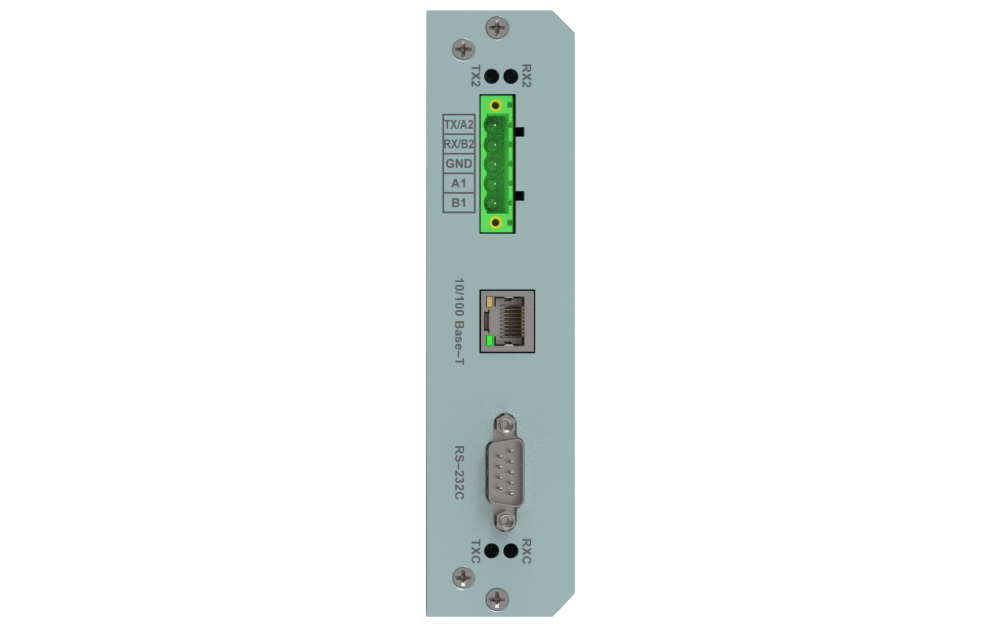

| Communication serial port on rear panel | RS232 & RS232/485 serial port |

| Communication ethernet port on rear panel | RJ45 Ethernet port |

| Communication protocol | IEC101/104, DNP3.0,MODBUS |

| Operation temperature range | -40°C..+70°C |

| Storage temperature range | -40°C...+85°C |

| Degree of protection | Front panel: IP54, Rear panel: IP20 |

| Dimension | 253*172*167 mm |

| Weight | 3.5 kg |