Solutions

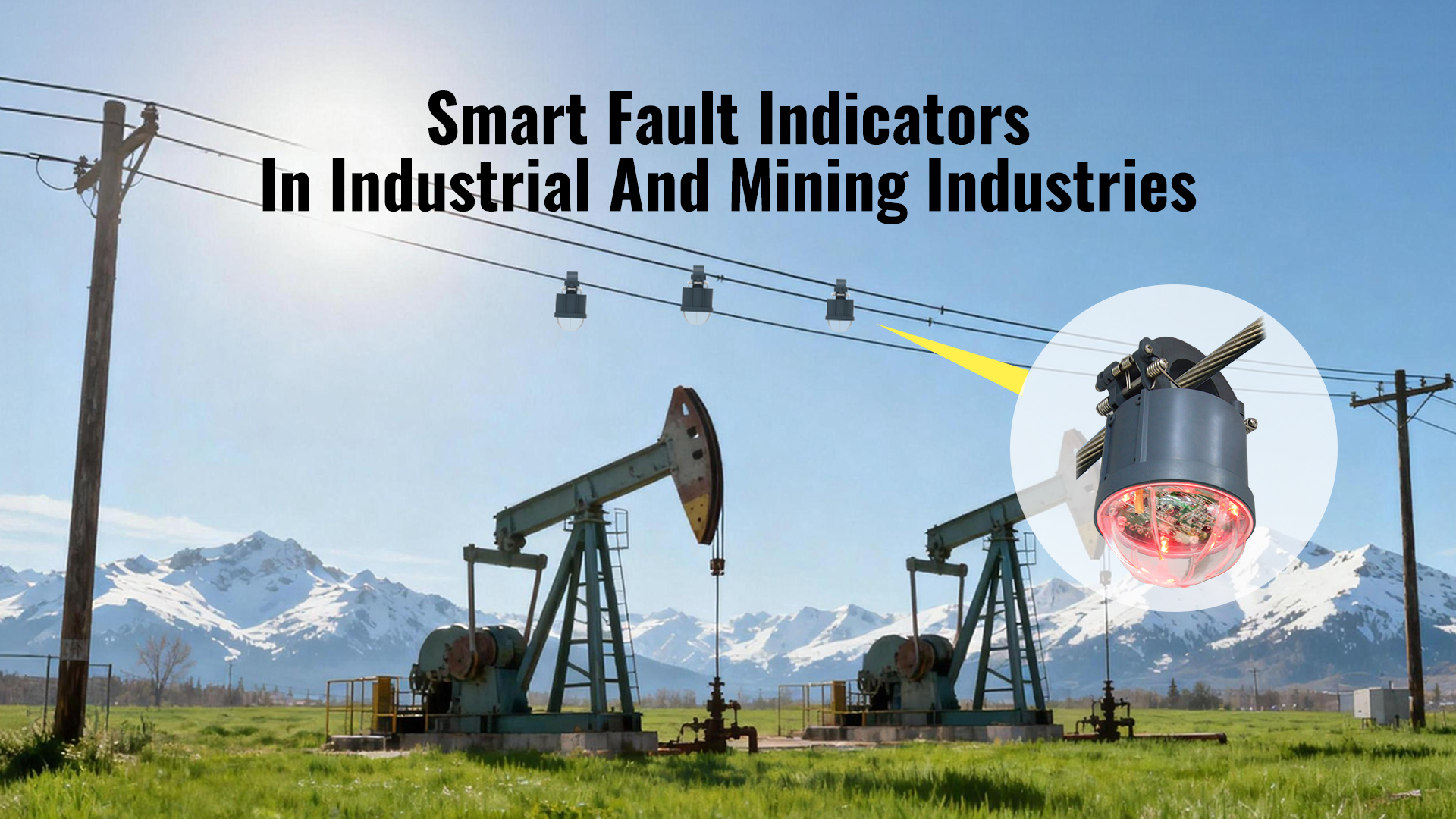

Smart Fault Indicators In Industrial And Mining Industries

Function highlights

Accurate Fault Detection – Real-time identification of short-circuit and grounding faults, pinpointing fault sections within minutes.

Fault Type Recognition – Distinguishes transient and permanent faults, reducing unnecessary outages.

Real-Time Monitoring – Tracks line current and temperature for early warning of overloads or loose connections.

Smart O&M – Data-driven maintenance cuts labor and patrol costs by over 70%.

Easy Integration – Supports IEC 101/104, DNP3, Modbus for seamless SCADA connection.

Rugged Design – IP68 protection, -40°C~+70°C range, ideal for harsh oilfield environments.

High Accuracy & Reliability – IEC-compliant algorithms, >90% fault detection accuracy, TUV certified.

Overview

Background

Client information:

Client Name: An oil company in the Middle East

Industry: Operation and maintenance of oil and mine overhead lines

Network Scale: Oilfield power distribution networks stretch for hundreds of kilometers, traversing complex mining terrain.

Original operation and maintenance model:

Fault location: Relying on manual sectionalizing and closing of circuit breakers for troubleshoot-ing, it takes an average of 24-72 hours to locate the fault point.

Labor costs: To ensure the safety of distribution lines, a large amount of manpower is required to conduct periodic inspections of the lines.

Data loss: Lack of effective online monitoring means the dispatching center has no knowledge of key operating parameters such as line load current and temperature, making it impossible to predict overload risks. Operation and maintenance decisions entirely rely on experience.

Economic and reputational losses: Oilfield production equipment stopped operating, and key processes such as drilling, oil production, and transportation were interrupted, causing economic losses of hundreds of thousands to millions per hour and seriously damaging the reputation of power companies.

Solution introduction

Four- Faith Smart Fault Indicator Solution:

Product Name: JYZ-HW Smart overhead line Fault Indicator

Core function description:

1) Accurate fault detection and location:

• Accurately detect short circuits and ground faults, and report alarm information in real time.

•Topology coloring function: The fault section is automatically displayed on the SCADA system(e.g. turns red), shortening the fault location time from days to minutes. The command center can direct-ly dispatch a team to the precise fault section.

2) Fault type identification and working condition judgment:

• Effectively identify transient faults and permanent faults to avoid unnecessary power outages.• Record the successful reclosing process, provide data for line health analysis, and reduce

unplanned power outages at the source

3) Real-time data monitoring and early warning:

• Continuously collect load current to warn of overload risks; monitor line temperature to detect hidden dangers such as loose connectors.• Data-driven decision-making: Personnel are dispatched only when equipment alarms or mainte-nance is required, reducing patrol mileage and manpower investment by more than 70%.

Deployment plan:

1. Live Installation: The live loading and unloading design is adopted without affecting the normal power supply.

2. Strong environmental adaptability: With high protection level(IP68) and wide operating tem-

perature(-40~ 70℃), it can adapt to the extreme environment of oil and mining areas.3) Seamless integration: Supports standard protocols such as IEC 60870-5-101/104, DNP3, and Modbus, allowing for quick integration with customers’ existing SCADA systems or Four-Faith micro-SCADA systems.

Feature and Benefit

Economic benefits:

1. Fault location time is reduced by more than 85%, significantly reducing production downtime losses.

2. Inspection mileage and labor costs are reduced by 50%-70%.

3. Extend the life of power equipment and optimize grid investment.

Management benefits:

1. Power supply reliability has been significantly improved, with customer complaints decreasing by more than 80%.

2. Establish a data-driven Smart operation and maintenance system to improve the level of refined management.

3. Greatly reduce the safety risks of on-site personnel.

Strategic benefits:

Create a “safe, efficient and reliable” modern green mining area power grid to ensure safe produc-tion of enterprises